As a fast response, high flow I/P, E/P transducer, the T5220 has all the performance you want in a voice coil I/P transducer product, but it also includes a built-in booster section to deliver high flow capacity, up to 45 SCFM (76.5 m3/HR), with six available ranges to allow pressure multiplication to the output.

As a fast response, high flow I/P, E/P transducer, the T5220 has all the performance you want in a voice coil I/P transducer product, but it also includes a built-in booster section to deliver high flow capacity, up to 45 SCFM (76.5 m3/HR), with six available ranges to allow pressure multiplication to the output.

Operating Principles

The T5220 Transducer is an electro-pneumatic device that converts a DC current or voltage input signal to a proportional pneumatic output. This device is made up of three sections: the Signal Conversion Section, the Pneumatic Section, and the Booster Section. The Signal Conversion Section (PC Board) accepts a DC current or voltage. This signal is applied to a coil, which creates a magnetic force that moves a Flexure Arm. The Pneumatic Section operates as a force balance system. A Sapphire Ball floats inside a Nozzle and controls the output pressure by exhausting air supplied through an Orifice. This Sapphire Ball acts as a piston, exerting a force that is balanced against the force transferred to the Flexure Arm by the Coil. The Booster Section amplifies the output pressure of the transducer. At the set point, the force due to the transducer output pressure acting on the top of the Upper Diaphragm is balanced by the force due to booster output pressure acting on the underside of the Lower Diaphragm. Any imbalance results in the actuation of the appropriate supply valve or exhaust valve to correct the output pressure.

Features

Model T5220 Electro-Pneumatic Transducer Features

- Fast response to input signal changes - results in faster loop control and savings in process materials

- Integrated volume booster output - high flow for a higher capacity output signal or pressure

- Six input signal ranges - meets most process and machine requirements

- Negative bias option allows zero-pressure-based operation

- Five booster ratios - meet industrial equipment requirements for higher output pressure ranges

- Temperature compensation provides stable operation under environmental changes

- Vibration resistance maintains set points under adverse vibration conditions

- Various mounting configurations - allows installation flexibility for most applications

- NEMA 3R or optional NEMA 4X enclosure - well-suited for outdoor and indoor installations

- Conduit port - allows for convenient wiring

Specifications

Model T5220 Electro-Pneumatic Transducer Specifications

- Supply Pressure: 20 + 2 psig, [1.5 + 0.15 BAR], (150 + 15 kPa)

- Output Capacity (SCFM): 15 (25.5 m3/HR) Max. @ 20 psig, [1.5 BAR], (150 kPa)supply. 45 (76.5 m3/HR) @ 100 psig, [7.0 BAR], (700 kPa) (with separate supply.)

- Exhaust Capacity (SCFM): 7 (11.9 m3/HR) downstream pressure @ 5 psig, [.35 BAR], (35 kPa) above 3 psig, [0.2 BAR], (20 kPa) set point. 14 (23.8 m3/HR) downstream pressure @ 5 psig, [.35 BAR], (35 kPa) above 15 psig, [1.0 BAR], (100 kPa) set point.

- Air Consumption (SCFM): 0.28 (0.48 m3/HR) Max. (dead end) @ 20 psig, [1.5 BAR], (150 kPa) supply

- Output Range (1:1 Ratio): 3-15 psig, [0.2-1.0 BAR], (20-100 kPa)

- Supply Pressure Effect: + 0.3% of Span for a 1 psig, [0.07 BAR], (7 kPa) supply change between 18-22 psig, [1.2-14.5 BAR], (120-145 kPa).

- Shock & Vibration Effect: Negligible up to 2 g's between 5 Hz and 200 Hz

- Ambient Temperature: -40° F to +150° F, (-40° C to +65.5° C)

- Temperature Coefficient: Less than 1% of Span / 50° F (10° C)

- Materials of Construction

- Body and Housing: Aluminum

- Ball and Orifice: Sapphire, Brass

- Nozzle: Stainless Steel

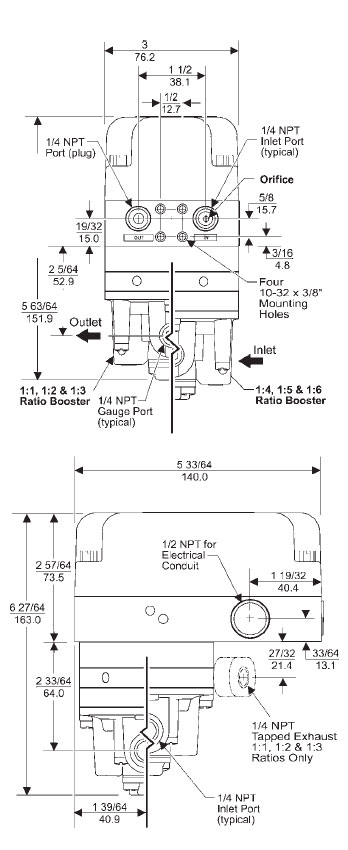

Dimensions

Model T5220 Electro-Pneumatic Transducer Dimensions

Q & A

Model T5220 Electro-Pneumatic Transducer Q & A

Downloads

Download Model T5220 Electro-Pneumatic I/P, E/P Transducer Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.