For precision instrument builders who need smooth motion in a small package, the mSR is a linear positioner that provides sub-micron level precision, in two different form factors and technologies, the 80 ironcore and 100 ironless. Learn more about Types of Linear Motors and the differences are between actuators, stages and positioners.

For precision instrument builders who need smooth motion in a small package, the mSR is a linear positioner that provides sub-micron level precision, in two different form factors and technologies, the 80 ironcore and 100 ironless. Learn more about Types of Linear Motors and the differences are between actuators, stages and positioners.

The mSR series consists of precision machined, square rail bearing guided linear positioners, which are driven with linear servo motors, and utilize selectable levels of linear encoder technologies configured to match the application need.

Within each form factor, OEMs have two options:

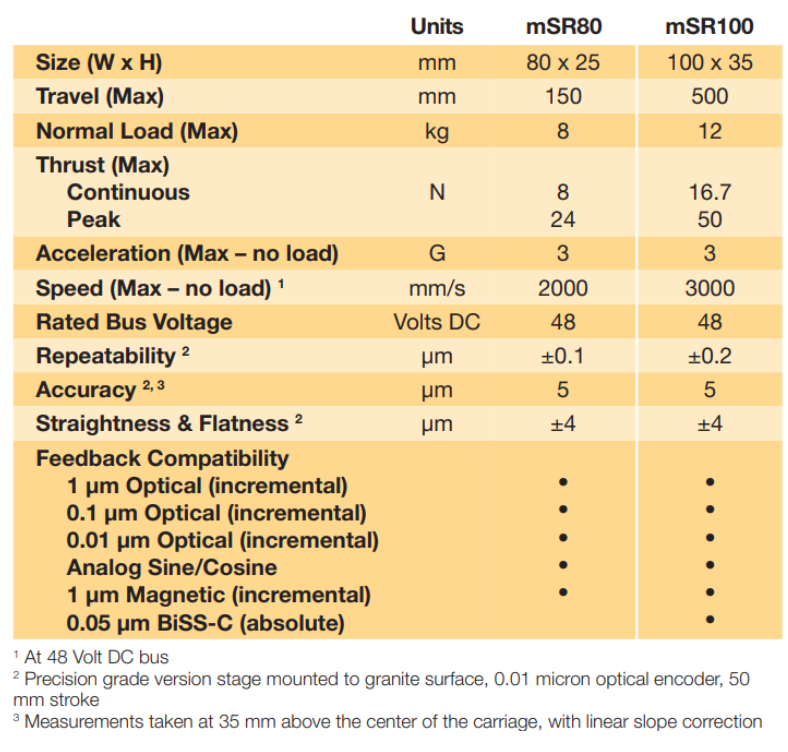

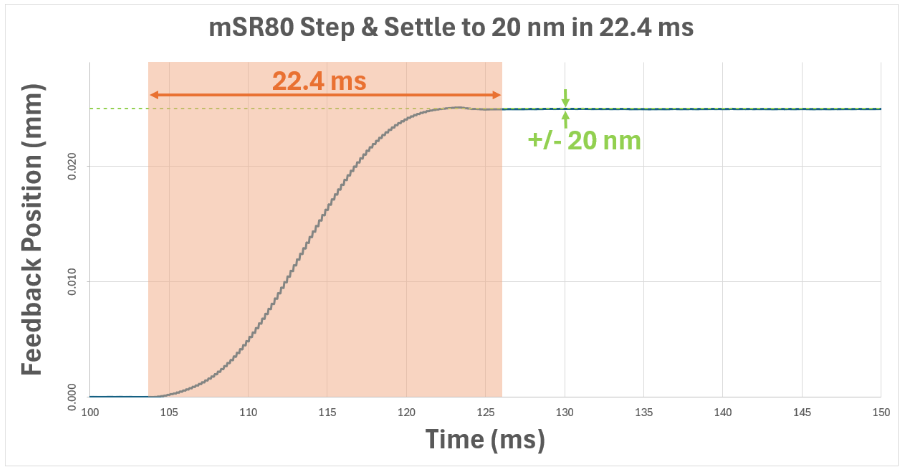

- The precision grade mSR is the most accurate standard positioner ever made by Parker, achieving repeatabilities of 100 to 200 nm with an accuracy of 5.0 microns over 50 millimeters of stroke.

- The more cost competitive standard version takes advantage of magnetic encoder technology, which is ideal for applications which do not require the same level of precision, to compete with similar ballscrew driven stages.

If you want to learn more about linear encoders, check out these episodes of The Motion Control Show:

These positioners are ideal for a variety of applications, ranging from imaging systems in digital pathology equipment to metrology instruments in semiconductor or electronics manufacturing.

Features

mSR Series Linear Motor Stages Features:

mSR Series Linear Motor Stages Features

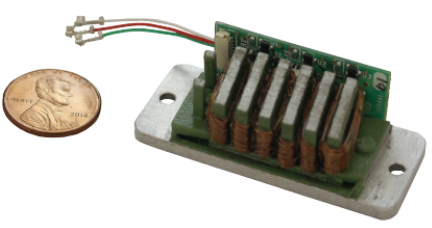

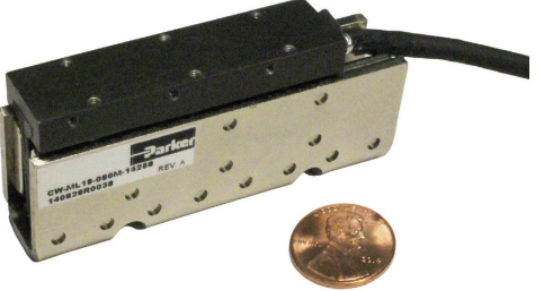

The mSR design has been optimized around two different linear motor technologies, ironcore and ironless, to best suit packaging restraints and application needs. Each of these motors has been optimized to deliver best-in-class performance and response. Both sizes are CE and RoHS compliant.

The mSR80 is ironcore to maximize the force for its size at a lower cost.

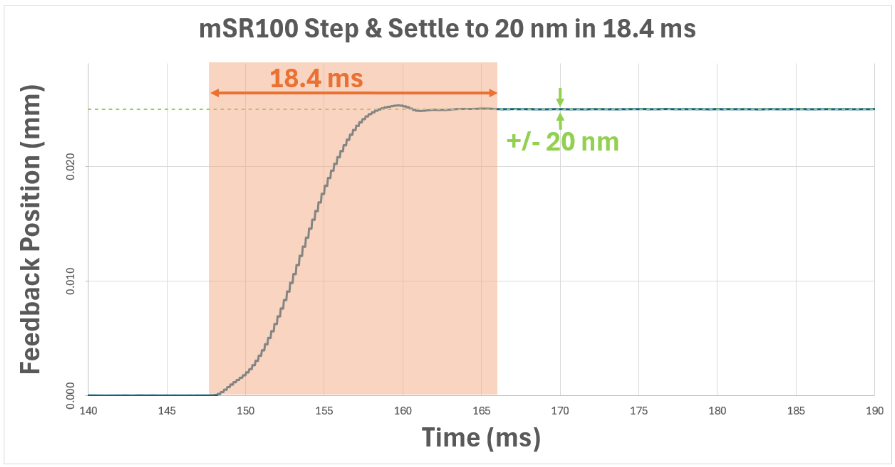

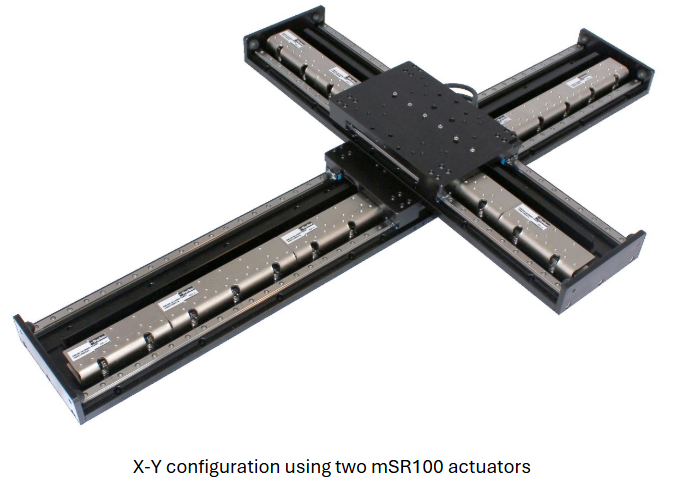

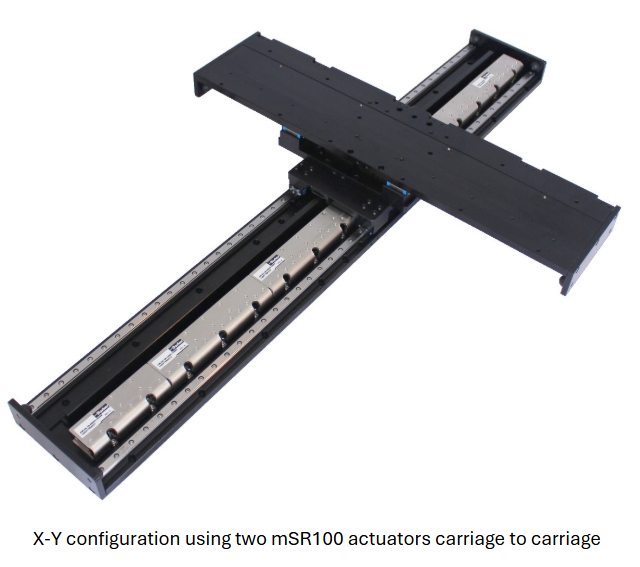

The mSR100 is ironless for the lower forcer weight and smoother motion.

Specifications

mSR Series Linear Motor Stages Specifications:

Full specifications can be found in the catalog and user manuals below.

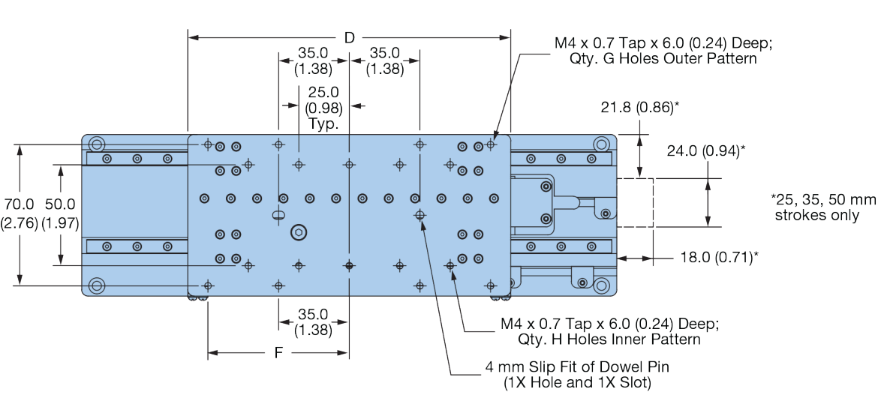

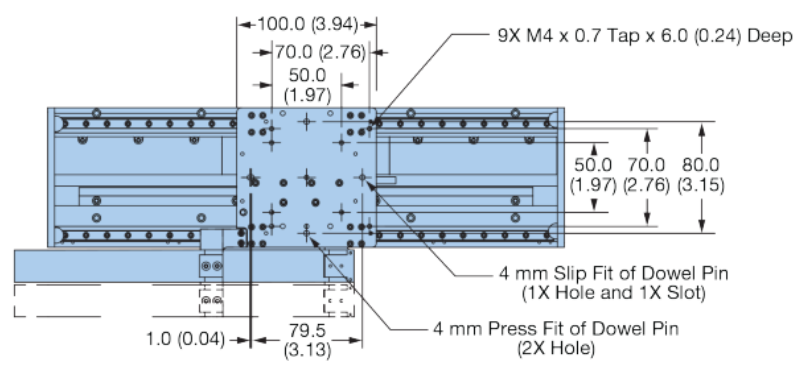

mSR BASIC DIMENSIONS:

The complete dimensions can be found in the catalog.

mSR80

mSR100

Applications

mSR Series Linear Motor Stages Application:

- Electronics Manufacturing

- Metrology

- Life Sciences

- Semiconductor

Q&A

mSR Series Linear Motor Stages Q & A:

Need cleanroom compatibility? The mSR series is available with cleanroom options and offers cable management solutions specifically designed to minimize particle generation. Its ironless linear motor also eliminates cogging, which enhances smooth motion – a requirement in sensitive environments like semiconductor fabs and biotech labs.

Looking to eliminate backlash and maintenance? Unlike ball screw-driven systems, the mSR Series uses a direct-drive linear motor and non-contact linear encoder. This design eliminates mechanical wear, reduces maintenance, and allows for higher accelerations, smoother motion, and better overall system reliability. Learn more about Ballscrew Actuators vs Belt Pulleys vs Linear Motors.

Want to dial in the perfect resolution? The mSR stages come with a range of non-contact linear encoder options, supporting up to 1 nm resolution. These options are factory-integrated and tested, reducing setup complexity and ensuring optimal performance right out of the box. Learn more about Linear Encoder Feedback: What To Know.

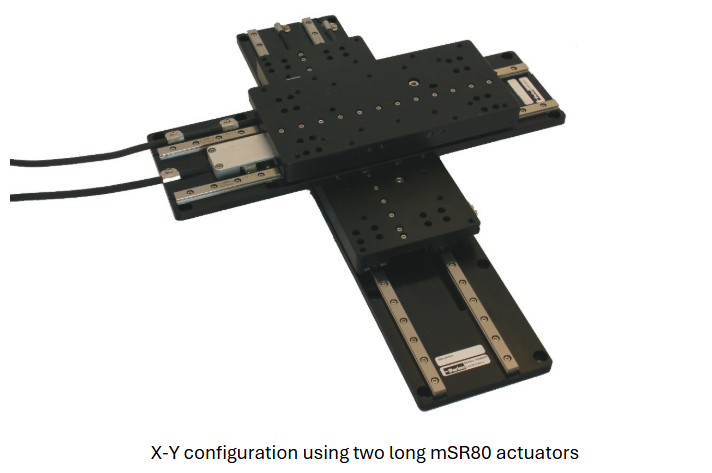

Thinking ahead to gantry or XYZ platforms? Yes – the mSR series is modular and can be easily combined into multi-axis configurations. With matching mounting surfaces and alignment features, you can build out a precision motion platform with fewer headaches and excellent geometric alignment. Learn more about Electric Actuators for Multi-Axis Configurations.