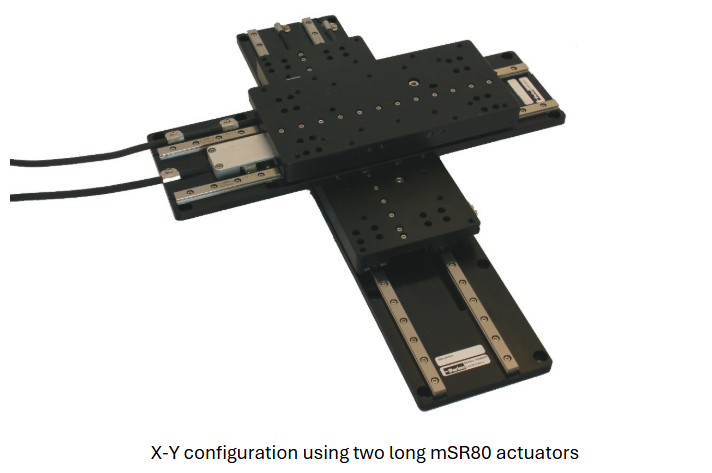

The mSR 80 is a miniature, high-precision linear positioner that uses dual precision grade square rails for its guidance, and an iron core linear motor for its drive. The mSR 80 has an extremely compact design measuring just 80 mm in width by 25 mm in height. Captured within this miniature profile is the stage's guidance, linear motor, linear encoder, as well as adjustable limit and home sensors making this an ideal positioner for space restricted applications in the life sciences or optics market. The mSR 80 can easily be configured into multi-axis configurations.

The mSR 80 is a miniature, high-precision linear positioner that uses dual precision grade square rails for its guidance, and an iron core linear motor for its drive. The mSR 80 has an extremely compact design measuring just 80 mm in width by 25 mm in height. Captured within this miniature profile is the stage's guidance, linear motor, linear encoder, as well as adjustable limit and home sensors making this an ideal positioner for space restricted applications in the life sciences or optics market. The mSR 80 can easily be configured into multi-axis configurations.

Features

Parker mSR 80 Series Linear Motor Positioner Features:

- Frame width of 80 mm

- Five standard strokes of 25, 35, 50, 100, and 150 mm

- Positional repeatability of +/- 0.1 micron

- Integrated magnetic (1.0 micron), optical (1.0, 0.1, 0.01 micron), or an analog Sine/Cosine encoder options

- Maximum speeds of 2000 mm/sec

- Optional 4 or 8 pole linear motor drivetrain options

- Maximum payload 78 N

- Maximum thrust of 24 N

- Integrated and adjustable home and limit sensing

- Standard multi-axis configurations available

- Laser test data with slope correction values with each precision grade stage

- Center Driven Ironcore Linear Motor: The mSR80 offers both 4 and 8 pole ironcore linear motors based upon the application thrust requirements. Each of these motors have been optimized to operate on 48 Volts DC.

- Optional Magnetic Counterbalance: The mSR80 with 25 mm stroke has an optional magnetic counterbalance that can be used for Z-axis applications. The magnetic counterbalance is a more robust solution when compared to spring or pneumatic driven alternatives. Learn more about why this is important: Linear Motors in Vertical Applications.

- High Flex Cabling: The mSR uses high-flex cabling as standard to ensure maximum life of the stage regardless of whether it’s integrated into a multi or single-axis system.

- Integrated & Adjustable Home & Limit Sensing: Home and limit sensors have been integrated into the mSR encoder read head, and signals are passed through the same cable, minimizing the number of cables requiring cable management

- Six Different Linear Encoder Technologies: The mSR provides maximum versatility with three different optical encoder resolutions (1, 0.1, and 0.01 micron), an analog sine/cosine option, an economical 1-micron magnetic option, and a 0.05-micron BiSS-C absolute option.

- The optical encoders offer exceptionally low sub-divisional errors, allowing for very tight control over velocity ripple.

- The analog (sine/cosine) encoder option is an ideal way to reach high resolution when paired with controls using interpolating technology to achieve high precision and high speed.

- The one-micron magnetic option is ideal for cost sensitive applications requiring more basic positioning

- The BiSS-C encoder option on the mSR 100 gives absolute feedback for applications requiring constant positional information.

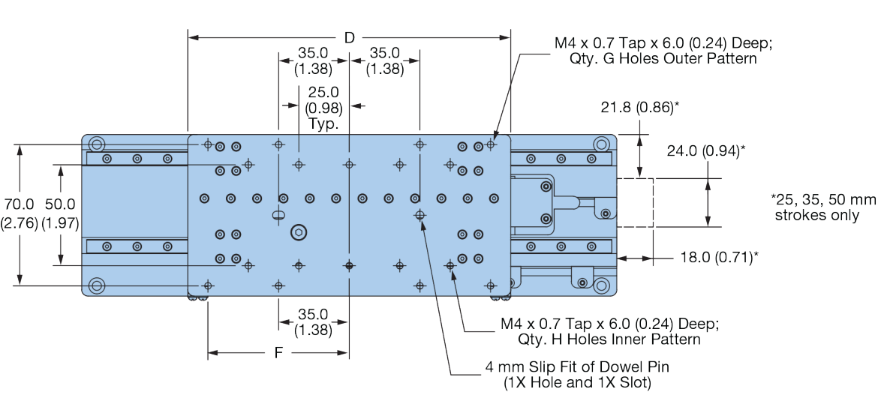

- Tapped Holes & Dowel Pinning: The mSR has tapped holes in both the top and base for ease of mounting and dowel pins to ensure repeatable mounting when configuring XY systems made with mSR positioners.

- Dual Precision Square Rails: Two precision aligned square rail bearings support the payload and provide superior straightness and flatness.

Specifications

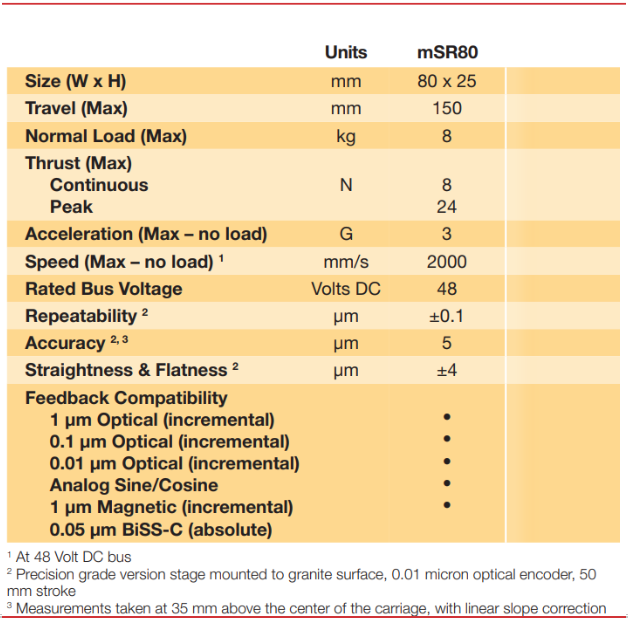

Parker mSR 80 Series Linear Motor Positioner Specifications:

mSR BASIC DIMENSIONS:

The complete dimensions can be found in the catalog.

mSR80

Applications

Parker mSR 80 Series Linear Motor Positioner Applications:

- Electronics Manufacturing

- Cleanroom

- Metrology

- Move/Transport

- Life Sciences

- Semiconductor

Q&A

Parker mSR 80 Series Linear Motor Positioner Q & A:

Yes, the mSR 80 is suitable for cleanroom applications. Its design minimizes particle generation, and with appropriate precautions, it can be used in environments requiring low contamination levels.

The mSR 80 features dowel holes for repeatable pinning, allowing for precise and secure mounting in various configurations.

Downloads

Parker mSR 80 Series Linear Motor Positioner Downloads:

Download Parker Miniature Positioners Linear Motor and Screw Driven Stages Catalog

Download Parker Miniature Square Rail Positioner Applications Brochure

Also, be sure to check out Parker's mSR 100 Series Linear Motor Positioner.

Call us today at (855) 737-4716 to learn more, or fill out our online form and someone will get back to you.