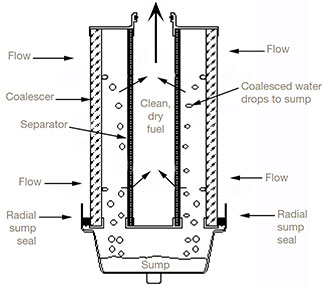

There are three distinct phases involved in removing or displacing water from another liquid. The first is particulate filtration. Many refer to this stage as prefiltration. During this phase, the goal is to remove as much particulate from a liquid as possible before it enters into the next portion of the process. During the second phase, coalescing, the liquid enters a coalescer where we develop small droplets of water where it then combines into larger droplets of water, making it easier to remove. During the third stage, separation, we’re aiming to completely separate the water from the rest of the liquid. Essentially, the separator will act as a screen and repel any water droplets that are still around the stream. However, the only way to ensure that this final stage does its job is to be confident that stages one and two are done properly. Part two (coalescing) is becoming more of an essential step in more and more industries, especially those that involve fuel and oil.

There are three distinct phases involved in removing or displacing water from another liquid. The first is particulate filtration. Many refer to this stage as prefiltration. During this phase, the goal is to remove as much particulate from a liquid as possible before it enters into the next portion of the process. During the second phase, coalescing, the liquid enters a coalescer where we develop small droplets of water where it then combines into larger droplets of water, making it easier to remove. During the third stage, separation, we’re aiming to completely separate the water from the rest of the liquid. Essentially, the separator will act as a screen and repel any water droplets that are still around the stream. However, the only way to ensure that this final stage does its job is to be confident that stages one and two are done properly. Part two (coalescing) is becoming more of an essential step in more and more industries, especially those that involve fuel and oil.

For coalescing to have the desired impact, it must be handled properly. This means walking through the process of properly sizing and specifying the tools we’re using for this stage. And this all starts with accurate inputs.

First, we must have a complete understanding of the operating parameters in a system. More specifically, we want to know the flow rate, operating pressure, operating temperature and the liquids at play.

Particulate filtration is an essential but not exactly a complicated exercise. You can be both cost conscious and effective in this stage as oversizing a filter will achieve both. When a filter is oversized, operators can be confident that the filter will do its job properly, and they will spend less time replacing them, saving on operating costs.

However, if you apply this principle to coalescing, it will no longer be effective. We must combine the particles, so knowing the flow rate is essential. If the rate is too low, the liquid may not separate. If it’s oversized, the velocity isn’t high enough to coalesce properly. When sizing the coalescer, we’re looking for optimal efficiency, staying within +/- 15% of the design operating parameters of the system: flowrate, temperature and pressure. The general principle of sizing is based off Stokes law.

Coalescing is a critical step in the filtration process. If you’re unsure about your setup, and want to ensure optimization, reach out to one of our experts to help walk you through what will work best for your process. Along with my colleague Joe Bodle, I wrote an article about this subject that was published in International Filtration News last year. Give it a read if missed it.