The ULTRAMIC? ceramic heater from Watlow? are designed for thermal applications where the high performance of an advanced ceramic heater is required to ensure optimal effectiveness of the equipment and process. ULTRAMIC ceramic heaters are constructed of aluminum nitride (AlN) and incorporate a thermally matched proprietary heating element that provides maximum performance in challenging applications. AlN is especially suitable for applications requiring a clean, non-contaminating heat source. Additionally, the excellent geometric stability ensures consistent part-to-part thermal contact during heating cycles. Watlow AlN ceramic heater can operate up to 400°C or 600°C (752°F or 1112°C) depending on lead construction with an ultra-fast ramp rate of up to 150°C (270°F) per second depending on the application, heater design and process parameters. In addition to excellent thermal characteristics, ULTRAMIC ceramic heater have high electrical isolation and typically provides superior chemical resistance as compared to traditional metal heaters.

The ULTRAMIC? ceramic heater from Watlow? are designed for thermal applications where the high performance of an advanced ceramic heater is required to ensure optimal effectiveness of the equipment and process. ULTRAMIC ceramic heaters are constructed of aluminum nitride (AlN) and incorporate a thermally matched proprietary heating element that provides maximum performance in challenging applications. AlN is especially suitable for applications requiring a clean, non-contaminating heat source. Additionally, the excellent geometric stability ensures consistent part-to-part thermal contact during heating cycles. Watlow AlN ceramic heater can operate up to 400°C or 600°C (752°F or 1112°C) depending on lead construction with an ultra-fast ramp rate of up to 150°C (270°F) per second depending on the application, heater design and process parameters. In addition to excellent thermal characteristics, ULTRAMIC ceramic heater have high electrical isolation and typically provides superior chemical resistance as compared to traditional metal heaters.

Features

ULTRAMIC? Advanced Ceramic Heater Features:

- Advanced Ceramic Heater Construction

- Constructing a Ceramic Heater - ULTRAMIC ceramic heaters are manufactured using a proprietary, sintering process. During sintering, ceramic powders are heated at a high temperature in a controlled environment, which facilitates densification and grain growth. A uniform grain size is created with no open porosity to ensure high mechanical strength and optimal thermal conductivity.

The green AlN matrix is constructed of two parts. The heating element is deposited on one of the AlN parts. Then, the parts are sintered together, making them one homogeneous assembly. The high thermal conductivity of AlN and an optimized circuit layout combine to produce superb temperature uniformity across the heater surface.

- Benefits of Aluminum Nitride (AIN) - Advanced ceramics are synthetic, inorganic compounds of exceptional

purity. Ceramic compounds include alumina (Al2O3), silicon nitride (Si3N4) and AlN.

AlN is an excellent choice for a ceramic heater platform as it allows for a homogeneous assembly for atmospheric or vacuum applications. The material also provides the durable heater construction and thermal transfer necessary for high temperature, fast cycling and long heater life.

- Constructing a Ceramic Heater - ULTRAMIC ceramic heaters are manufactured using a proprietary, sintering process. During sintering, ceramic powders are heated at a high temperature in a controlled environment, which facilitates densification and grain growth. A uniform grain size is created with no open porosity to ensure high mechanical strength and optimal thermal conductivity.

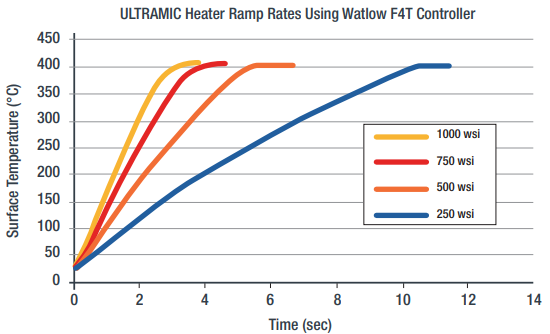

- Ultra-Fast Ramp Rates

- With the ongoing push for equipment productivity, improving heat/cool cycle times is one way to optimize system performance. The high thermal conductivity of AlN allows the ULTRAMIC heater to heat and cool quickly, and to be constructed with extremely high watt densities of up to 1000 W/in2. These high watt densities enable ramp rates as high as 150°C (270°F) per second, resulting in higher productivity in applications such as semiconductor chip testing and eutectic die bonding.

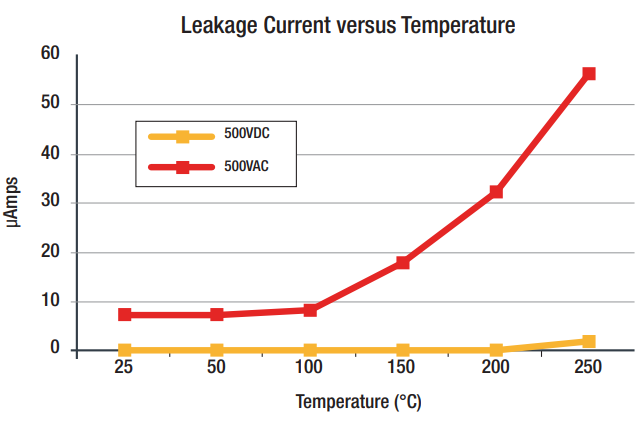

- Low Leakage Current

For many applications, such as medical devices, extremely low leakage current is critical for patient safety or system

performance. To meet agency regulations, many device manufacturers resort to using step down isolation transformers and low voltage power supplies to enable the use of traditional heating technologies. These transformers add size, weight and cost to the system. In many cases, an ULTRAMIC heater can eliminate the need for these transformers by providing the required electrical performance, even at standard line voltages, in a small, clean package.

- Product Design Capability

- Application Miniaturization - Miniaturization, or reducing the size of products and components, is an ongoing effort in virtually all industries. Parallel with reducing size is the need for increased precision and reduced system cost. With sizes as small as 8 mm (0.31 in.) and green state CNC machining capability, ULTRAMIC heaters help

meet these needs and can often replace multiple components in a system. - Integrated Temperature Sensor - Watlow’s ULTRAMIC heater with integrated Type K thermocouple or 100 Ohm RTD, provides a convenient way of controlling temperature with a high watt density heater without going through the trouble of installing a separate temperature sensor. The benefits of using an integrated sensor include:

- Ensures reliability of heater/sensor interface with the bonded assembly process

- Improves accuracy with optimized temperature sensing

- Provides high response rate in ramping applications

- Lead Wire and Terminations - Various lead wire and termination options are available to meet specific application needs. Some of these options include:

- Power terminals exit locations — extended from the side or from the face of the heater

- PTFE? insulated silver-plated copper lead extension wires

- Lead extension length — standard length 305 mm (12 in.)

- Ceramic breads

- Mounting Guidelines - This product can be mounted within a system in numerous ways. The mounting guidelines depend on the temperature and the application. Below are general rules for mounting:

- Temperature <200oC (392oF): bond with high-temperature epoxy adhesive

- Temperature <200oC (392o): screw hole can be provided (recommend insulation buffer such as mica spacer)

- Clamp using single or multiple-point fasteners

- Application Miniaturization - Miniaturization, or reducing the size of products and components, is an ongoing effort in virtually all industries. Parallel with reducing size is the need for increased precision and reduced system cost. With sizes as small as 8 mm (0.31 in.) and green state CNC machining capability, ULTRAMIC heaters help

Specifications

ULTRAMIC? Advanced Ceramic Heater Specifications:

| Description | Information |

| Material | Aluminum Nitride |

| Maximum Operating Temperature - C | 400 / 600 oC |

| Maximum Operating Temperature - F | 752 / 1112 oF |

| Maximum Watt Densities | 155 W/cm^2 |

| Maximum Watt Densities | 1000 W/in^2 |

Q&A

ULTRAMIC? Advanced Ceramic Q & A:

Downloads

Download ULTRAMIC? Advanced Ceramic Heater Brochure

Talk to one of our process control experts today at (855) 737-4714, or fill out our online form to learn more.