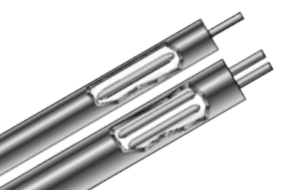

MI Mineral Insulated Heating Cable

MI mineral insulated heating cables provide rugged and reliable heat tracing for a variety of demanding applications. The high nickel alloy sheath, magnesium oxide dielectric insulation and resistance wire construction allow the tracing of equipment up to 1100F maintenance temperatures and excellent resistance to many corrosive environments. At lower temperatures, watt densities of up to 50 W/Ft can be designed. Please contact factory for cable maintenance temperature above 400F.

Features

- Constant Wattage Series Resistance Heating Cable Sets

- Process Temperature Maintenance to 900F

- Maximum Exposure Temperature (Power Off) 1100F

- Wattages up to 50 W/Ft.

- Corrosion Resistant, Alloy 825 Sheath

- Factory Assembled Cable SetsReady for Installation

- Fully Annealed Sheath allows Field Bending

- Suitable for Hazardous Areas, Div. 1 and Div. 2

Applications

- Tank Heating

- High Temperature Process Maintenance

- Long, Single Circuit Runs

- Cryogenic Applications

- Freeze Protection

Download the MI Mineral Insulated High Temperature Heating Cable Datasheet

Hands-On Assistance from Technical Specialists

Need help?

Fill out our heat trace application form and we will have one of our process heating experts contact you, or call (855) 737-4718 to speak to one of our experts immediately.

MI mineral insulated heating cables provide rugged and reliable heat tracing for a variety of demanding applications with temperatures up to 400F and special order cable to 1100F