Designed for use in hazardous environments, the Rotork Fairchild TXI7800 series product is an explosion-proof I/P pressure transducer. It operates under the same principles as the T7800 product; however, the TXI series includes NEMA 4X explosion-proof construction. Our design isolates the electronics chamber from the pneumatic section, thereby creating a safer and longer service life product, especially for applications handling natural gas.

Designed for use in hazardous environments, the Rotork Fairchild TXI7800 series product is an explosion-proof I/P pressure transducer. It operates under the same principles as the T7800 product; however, the TXI series includes NEMA 4X explosion-proof construction. Our design isolates the electronics chamber from the pneumatic section, thereby creating a safer and longer service life product, especially for applications handling natural gas.

Operating Principles

The Model TXI7800 Transducer is an electronically controlled pressure-sensitive device that converts a current signal to a pneumatic output. This device is composed of the Primary Converting Section and the

Relay Section. The Piezoelectric ceramic disk in the Primary Section functions as a flapper. The flapper and the nozzle work together to control the signal pressure in the Relay Section. The signal pressure acts on a diaphragm assembly that controls the pressure in the output chamber.

The output pressure is sensed by the lower control diaphragm to maintain the output pressure. The output pressure is also sensed by the feedback control circuit, which compares the output pressure and input signal (setpoint) to maintain constant output pressure.

The Damping Adjustment on the PC Board allows tuning the transducer for optimum response and stability. Large downstream volumes generally require more damping to achieve output pressure stability.

Features

Model TXI7800 Explosion-Proof Transducer Features

- In the Extended Range units, the TXI7800 series will also deliver up to 0-120 psi [0-8.0 BAR], (0-800 kPa) output.

- 18 available output ranges - tremendous versatility for application design.

- Accuracy as low as 0.15% - high precision, reliable operation.

- Field selectable outputs in three pressure ranges - easily match final control element requirements.

- Field reversible feature provides an output directly or inversely proportional to the input signal.

- Does not contain copper-based metals - designed for use with natural gas and corrosive media.

- Optional version approved for use with natural gas or industrial methane supply media.

- Explosionproof NEMA 4X, IP65, Type 4 enclosure - allows for outdoor and indoor installations.

- FM, CSA, ATEX, and IECEx approvals - carry global approval for intrinsic safety and hazardous location operation.

- Canadian registration numbers (CRN) certifications - may be used in all territories and provinces.

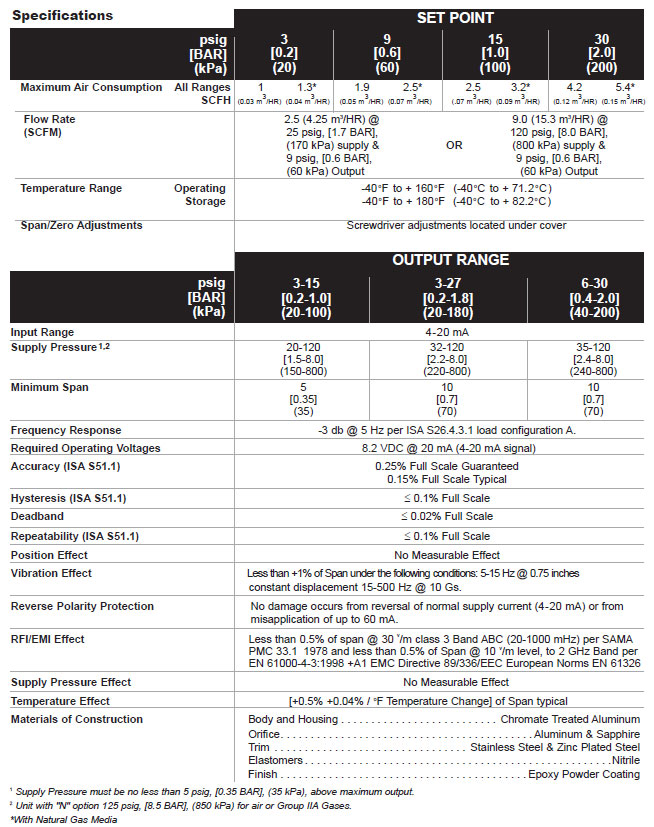

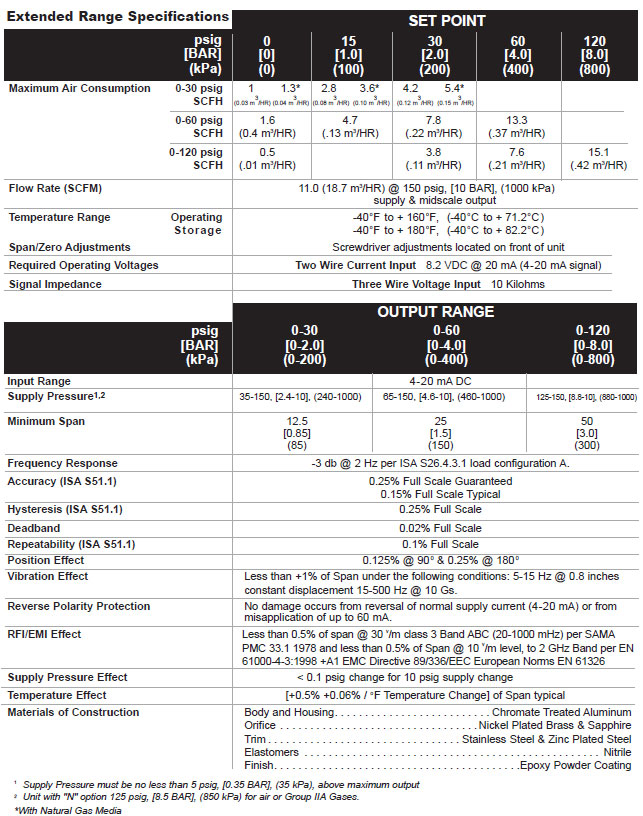

Specifications

Model TXI7800 Explosion-Proof Transducer Specifications

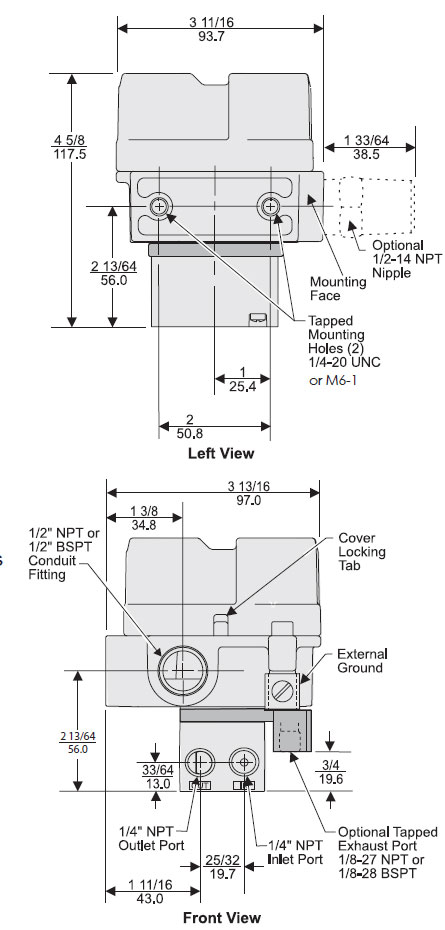

Dimensions

Model TXI7800 Explosion-Proof Transducer Dimensions

Q & A

Model TXI7800 Explosion-Proof Transducer Q & A

Downloads

Download Rotork Fairchild Model TXI7800 Explosion-Proof Transducer Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form, and someone will get back to you.