This high-temperature thermocouple with a gas-tight sapphire protection tube has been specifically developed for use in gasification reactors. Through the monocrystalline structure, the sapphire protects the precious metal of the thermocouple from poisonous toxic media in the aggressive atmosphere of the gasification reactor.

This high-temperature thermocouple with a gas-tight sapphire protection tube has been specifically developed for use in gasification reactors. Through the monocrystalline structure, the sapphire protects the precious metal of the thermocouple from poisonous toxic media in the aggressive atmosphere of the gasification reactor.

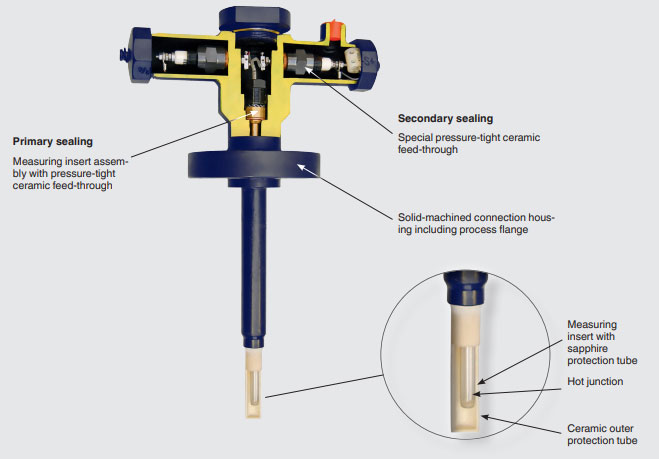

This solution has been used successfully in different reactors worldwide since 1997 under the designation model T-FZV. Hermetically sealed, pressure-tight junctions between the sapphire and metal protection tube, and also a multifold sealing system in the connection housing prevents toxic gases from being able to escape the reactor.

The high temperatures and pressures in the gasification process place very high demands on protection tubes and thermocouples. These process conditions often lead to shutdowns and interruptions in operation. Utilizing the patented sapphire design can significantly improve life expectancy and reduce downtime.

Features

Model TC84 Sapphire-Design Thermocouple Features

- 3 times longer service life in comparison to purely ceramic protection tubes due to the monocrystalline structure of the sapphire sensor

- High process safety with processes up to 1,700° C [3,092° F] and 65 bar [943 psi]

- Reduction of unplanned downtime

- Increased safety through a double sealing system against the escape of toxic media

- Cost savings through the elimination of a purge system and the repairability of the sensor

Specifications

Model TC84 Sapphire-Design Thermocouple Specifications

Protection mechanisms

The primary sealing serves as protection against the escape of media from the process at high pressures and temperatures.

The secondary sealing is the safeguard in the event of a malfunction in the primary seal due to any unforeseeable disturbance.

Double-protected sensor tip

Ceramic outer protection tube for protection against harsh process conditions.

Sapphire measuring insert protection tube for internal protection against contamination of the thermocouples through diffusion.

Applications

Model TC84 Sapphire-Design Thermocouple Applications

- Gasification reactors

- GtL reactors (Gas-to-Liquids)

- Sulphur recovery plants

Q & A

Model TC84 Sapphire-Design Thermocouple Q & A

The patented sapphire protection tube delivers multiple operational advantages:

- Extended service life — about 3× longer than standard ceramic assemblies.

- Enhanced process safety — protects the thermocouple from toxic media and hydrogen permeation.

- Reduced maintenance and downtime — eliminates the need for purge systems and costly frequent replacements.

- Improved sealing — double sealing system prevents escape of hazardous gases.

These benefits directly translate to lower total cost of ownership (TCO) and greater uptime.

Customers typically buy the TC84 for critical high-temperature process measurement, including:

- Gasification reactors

- GtL (Gas-to-Liquids) reactors

- Sulfur recovery units

- Other high-temp processing units in petrochemical, refining, and syngas facilities

This thermocouple is specifically chosen when reliability under extreme heat and corrosive atmospheres is paramount.

When specifying your TC84 product, the main decisions include:

- Thermocouple Type: Options such as Type S, R, or B, depending on your temperature range and accuracy requirements.

- Process Connection: Available in ASME flanges (1-1/2″ to 4″) or EN 1092-1 (DN 40 to DN 100) to match your piping or vessel interface.

- Outer Protection Material: A ceramic outer protection tube provides mechanical durability, while the sapphire inner tube protects against chemical attack.

Work with Valin's temperature measurement experts to match your process media, purge requirements, and compliance standards (e.g., IECEx, CE) for optimal performance and safety.

Downloads

Read Case Study: WIKA Equips Syngas Plant with Long-Lasting Thermocouples

Download WIKA Model TC84 Sapphire-Design Thermocouple Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form, and someone will get back to you.