The T7500 series low-pressure transducer converts a DC electronic input signal to a proportional low-pressure pneumatic output. The transducer employs electronic closed-loop feedback in conjunction with a piezoceramic actuator flapper nozzle system in the pilot stage to control the signal pressure of an integral pneumatic volume booster.

The T7500 series low-pressure transducer converts a DC electronic input signal to a proportional low-pressure pneumatic output. The transducer employs electronic closed-loop feedback in conjunction with a piezoceramic actuator flapper nozzle system in the pilot stage to control the signal pressure of an integral pneumatic volume booster.

Rotork Fairchild’s T7500 series I/P Transducer delivers the highest setpoint accuracy at low output pressure ranges of 0-2.5, 0-5, 0-7.5, and 0-15 psig. Output pressure ranges can be ranged down to as low as 0-1 psig.

Using proprietary pneumatic and electronic design, the T7500 accepts supply pressures from 20-30 psig (1.5-2 bar) and mA or VDC control signals to proportionally control the output pressure in very low ranges. While most transducers struggle to accurately and repeatedly hold a low-pressure output setpoint, the T7500 will provide 0.25% or better accuracy at pressure ranges as low as 0-1 psig (0-69 mbar) output.

The T7500 is available in a variety of configurations for electrical connection and can be mounted with its standard supplied bracket or DIN rail mounted.

Features

Model T7500 Low Pressure Electro-Pneumatic Transducer Features

- The volume booster employs a highly sensitive control diaphragm and main valve to accurately control the flow of air to the downstream system in response to the pressure received from the pilot stage. The electronic closed-loop feedback senses the output pressure of the volume booster directly to affect the ultimate in accurate pressure control.

- 4 available output ranges - tremendous versatility for application design.

- Accuracy as low as 0.15% - high precision, reliable operation.

- Field reversible feature provides an output inversely proportional to the input signal.

- RFI/EMI protection eliminates susceptibility to electromagnetic and radio interference.

- Internal electronic feedback and a piezoelectric actuator provide precise control of output pressure regardless of vibration or position.

- Damping adjustment allows for optimum tuning response.

- Split range operation allows a common signal source to control two or more functions.

- NEMA 4X, type 4 enclosure and IP65 rated - Suitable for indoor and outdoor installations.

- Compact size for use in restricted spaces.

- Accepts 20-30 psig (1.5-2 bar) supply.

- Controls output pressure ranges as low as: 0-1 psig (69 mbar).

Specifications

Model T7500 Low Pressure Electro-Pneumatic Transducer Specifications

- Supply Pressure: 20-30 psig (1.5-2.0 bar)

- Accuracy (ISA S51.1)

- 0.25% Full scale guaranteed

- 0.10% Full scale typical

- Flow Rate (SCFM)

- T7501: 3.0 (5.1 m3/hr) @ 30 psig (2 bar) supply 5 psig (0.3 bar) output

- T7502: 7.0 (11.9 m3/hr) @ 30 psig (2 bar) supply 5 psig (0.3 bar) output

- Supply Voltages: Three-wire voltage input: 7.2 to 30 VDC, <3 mA

- Control Signals

- 4-20 mA 2-wire

- 0-5 VDC 3-wire

- 0-10 VDC 3-wire

- Materials of Construction

- Body and Housing: Chromate-treated Aluminum

- Orifice: Nickel-plated Brass & Sapphire

- Trim: Stainless steel, Brass & Zinc-plated Steel

- Elastomers: Nitrile

- Finish: Epoxy powder coating

Dimensions

Model T7500 Low Pressure Electro-Pneumatic Transducer Dimensions

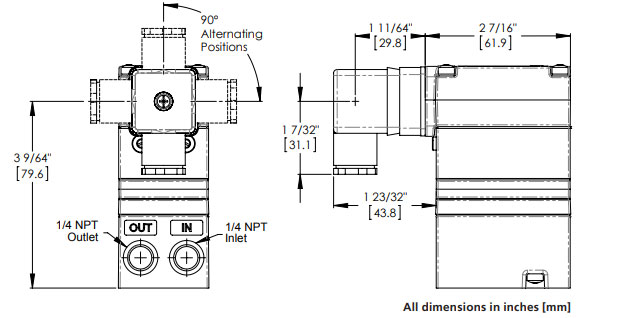

TD7500 Dimensions

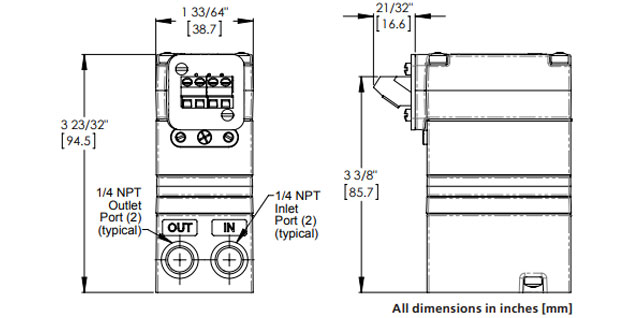

TT7500 Dimensions

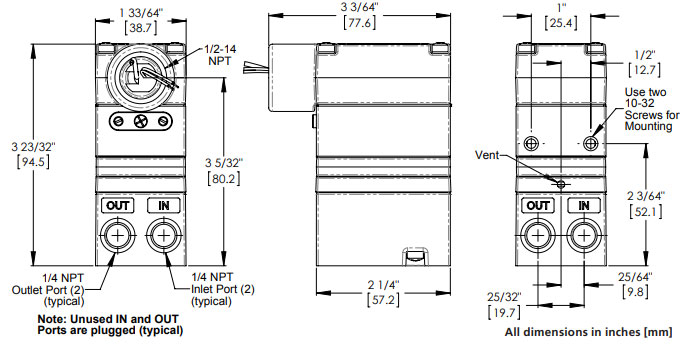

TA7500 Dimensions

Q & A

Model T7500 Low Pressure Electro-Pneumatic Transducer Q & A

Downloads

Download Rotork Fairchild Model T7500 Compact E/P, I/P Low Pressure Transducer Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form, and someone will get back to you.