Model 4800A is a High Flow Pneumatic Volume Booster specifically designed for Valve and valve actuation systems. With its Cv of 9 in both forward and exhaust modes, this pilot-operated booster provides fast response and accurate control for valve actuation.

Model 4800A is a High Flow Pneumatic Volume Booster specifically designed for Valve and valve actuation systems. With its Cv of 9 in both forward and exhaust modes, this pilot-operated booster provides fast response and accurate control for valve actuation.

Operating Principles

When signal pressure on the top of the Signal Diaphragm creates a downward force on the Diaphragm Assembly, the Supply Valve opens. Output pressure flows through the Outlet Port and the Aspirator Tube to the Control Chamber to create an upward force on the bottom of the Control Diaphragm. When the setpoint is reached, the force of the signal pressure that acts on the top of the Signal Diaphragm balances with the force of the output pressure that acts on the bottom of the Control Diaphragm to close the Supply Valve.

When the output pressure increases above the signal pressure, the Diaphragm Assembly moves upward to close the Supply Valve and open the Exhaust Valve. Because the Poppet Valve is closed, pressure flows down the Connecting Tube to the bottom of the Motor Diaphragm. This pressure keeps the Supply Valve tightly closed while in the exhaust mode. The Poppet Valve opens and excess output pressure exhausts through the vent in the side of the unit until it reaches the setpoint.

Features

Model 4800A Volume Booster Features

- An integral bypass valve, for optimum tuning and adjustment, even while in operation, to obtain maximum performance on opening and closing times with minimal overshoot or oscillation

- In its pilot-operated regulator design, the M4800A handles up to 250 psig, [17.0 BAR], (1700 kPa) supply pressure and delivers an output pressure up to 150 psig [10.0 BAR] (1000kPa)

- Cv = 9; Flow capacity of 500 SCFM (850 m3/HR) - fast response for quick valve opening and closing times

- Ratio accuracy of 0.5% - highly accurate valve control for your system

- Fixed deadband between the operation of the supply valve and exhaust valve provides accurate and stable final positioning of the valve

- Integral bypass needle valve optimizes response time and stability

- Soft seat supply and exhaust valves provide efficient leak-free operation and prevent hunting, especially when used with modern electronic feed & bleed type valve positioners

- Pressure-balanced supply valve maintains deadband specification, preventing changes in control characteristics when supply pressure changes

- Damped diaphragm control chamber protects valves from damaging oscillation under high flow conditions

- Two accessory ports connected to the outlet chamber provide convenient access to the outlet for additional control accessories and pressure monitoring

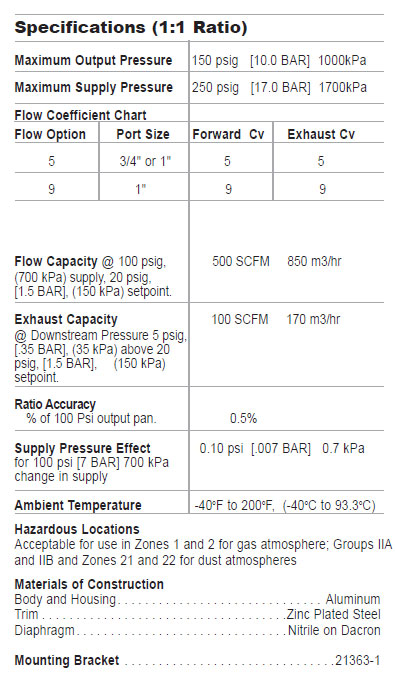

Specifications

Model 4800A Volume Booster Specifications

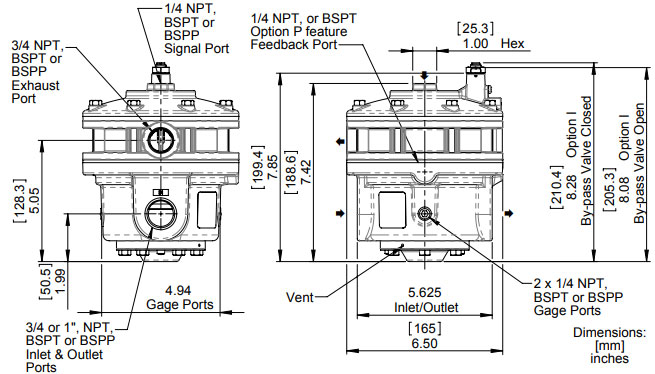

Dimensions

Model 4800A Volume Booster Dimensions

Q & A

Model 4800A Volume Booster Q & A

Downloads

Download Rotork Fairchild Model 4800A Volume Booster Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.