The Model 2000 Pneumatic Volume Booster converts a low-flow signal to a high-flow output. It is ideally suited for a variety of applications, including the operation of air systems that require rapid valve or cylinder action. With its balanced supply valve and aspirator tube, the M2000 booster will maintain setpoint while delivering a strong boost of volume.

The Model 2000 Pneumatic Volume Booster converts a low-flow signal to a high-flow output. It is ideally suited for a variety of applications, including the operation of air systems that require rapid valve or cylinder action. With its balanced supply valve and aspirator tube, the M2000 booster will maintain setpoint while delivering a strong boost of volume.

Operating Principles

When signal pressure on the top of the Signal Diaphragm creates a downward force on the Diaphragm Assembly, the Supply Valve opens.

Output pressure flows through the Outlet Port and the Aspirator Tube to the Control Chamber to create an upward force on the bottom of the Control Diaphragm. When the setpoint is reached, the force of the signal pressure that acts on the top of the Signal Diaphragm balances with the force of the output pressure that acts on the bottom of the Control Diaphragm to close the Supply Valve.

When the output pressure increases above the signal pressure, the Diaphragm Assembly moves upward to close the

Supply Valve and open the Exhaust Valve. Because the Poppet Valve is closed, pressure flows down the Connecting Tube to the bottom of the Motor Diaphragm. This pressure keeps the Supply Valve tightly closed while in the exhaust mode. The Poppet Valve opens and excess output pressure exhausts through the vent in the

side of the unit until it reaches the setpoint.

Features

Model 2000 Volume Booster Features

- Flow capacity of 40 SCFM (68 m3/HR), which results in a Cv factor of just less than 1.0 in forward flow mode - provides fast responsive operation

- Balanced supply valve minimizes the effect of supply pressure variation

- Aspirator tube design minimizes downstream pressure droop under flow conditions

- Soft supply and exhaust valve seats provide high forward and exhaust flows

- Small signal volume - assures rapid response to pressure variation

- A separate control chamber isolates the diaphragm from the main flow and eliminates any hunting and buzzing

- Unit construction allows you to service the unit without removing it from the line

- No bleed soft seat design minimizes the air consumption of the system

Specifications

Model 2000 Volume Booster Specifications

- Maximum Supply Pressure: 250 psig, [17.0 BAR], (1700 kPa)

- Flow Capacity (SCFM): 40 (68 m3/HR) @ 100 psig, [7.0 BAR], (700 kPa) supply & 20 psig, [1.5 BAR], (150 kPa) setpoint

- Exhaust Capacity (SCFM): 16 (27.2 m3/HR) where downstream pressure is 5 psig,[.35 BAR], (35 kPa) above 20 psig, 1.5 BAR], (150 kPa) setpoint

- Maximum Signal or Output Pressure: 150 psig, [10.0 BAR], (1000 kPa)

- Supply Pressure Effect: Less than 0.1 psig, [.007 BAR], (.7 kPa) for 100 psig, [7.0 BAR], (700 kPa) change in supply pressure

- Sensitivity: Less than 1” (2.54 cm) Water Column

- Ambient Temperature: -40° F to +200°F, (-40° C to +93° C)

- Materials of Construction:

- Body and Housing: Zinc

- Diaphragms: Nitrile on Dacron

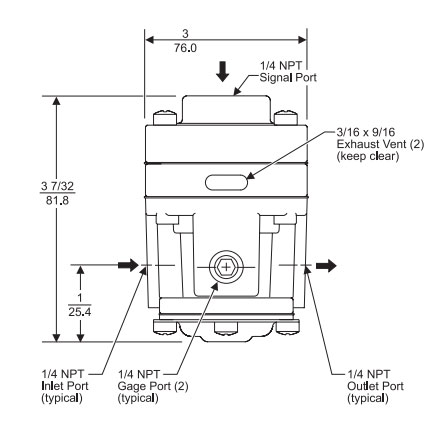

Dimensions

Model 2000 Volume Booster Dimensions

Q & A

Model 2000 Volume Booster Q & A

Downloads

Download Rotork Fairchild Model 2000 Volume Booster Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.