The Fairchild Model 200 pneumatic volume booster reproduces a pneumatic signal in a 1:1 ratio. It is ideally suited for systems that require input isolation or increased forward flow capacity.

The Fairchild Model 200 pneumatic volume booster reproduces a pneumatic signal in a 1:1 ratio. It is ideally suited for systems that require input isolation or increased forward flow capacity.

Operating Principles

When signal pressure on the top of the signal diaphragm creates a downward force on the diaphragm assembly, the supply valve opens. Output pressure flows through the outlet port and the aspirator tube to the control chamber to create an upward force on the bottom of the control diaphragm. When the setpoint is reached, the downward force of the signal pressure that acts on the top of the signal diaphragm balances with the upward force of the output pressure that acts on the bottom of the control diaphragm and closes the valve to maintain the setpoint.

When the output pressure increases above the signal pressure, the diaphragm assembly moves upward to close the supply valve and open the exhaust valve. Excess output pressure exhausts through the vents in the side of the unit until it reaches the setpoint.

Features

Model 200 Volume Booster Features

- Control sensitivity to 1" water column variation

- Large supply and exhaust valves provide high forward and exhaust flows

- A balanced supply valve minimizes the effect of supply pressure variation

- An aspirator tube minimizes downstream pressure drop under flow conditions

- A separate control chamber isolates the diaphragm from the main flow to eliminate hunting and buzzing

- Optional increased sensitivity configuration with larger control diaphragm for more precision control at low setpoints

- Unit construction lets you service the Model 200 without removing it from the line

- Mounting bracket is available

Specifications

Model 200 Volume Booster Specifications

- Maximum supply pressure: 250 psig, [17.0 bar], (1700 kPa)

- Flow capacity: 1800 SCFM (3058 m3/hr) @ 150 psig, [10.0 bar], (1000 kPa) supply, 20 psig, [1.5 bar], (150 kPa) setpoint

- Exhaust capacity: 65 SCFM (110.5 m3/hr) where downstream pressure is 5 psig, [0.35 bar], (35 kPa) above 20 psig, [1.5 bar], (150 kPa) setpoint

- Maximum signal or output pressure: 150 psig, [10 bar], (1000 kPa)

- Supply pressure effect: Less than 0.5 psig, [0.035 bar], (3.5 kPa) for 100 psig, [7.0 bar], (700 kPa) change in supply pressure

- Sensitivity: 1” (2.54 cm) water column

- Ambient temperature: -40 to +200 oF, (-40 to +93.3 oC)

- Materials of construction:

- Body and housing: Aluminum

- Trim: Aluminum, stainless steel, zinc plated steel, brass

- Diaphragms: Nitrile on polyester

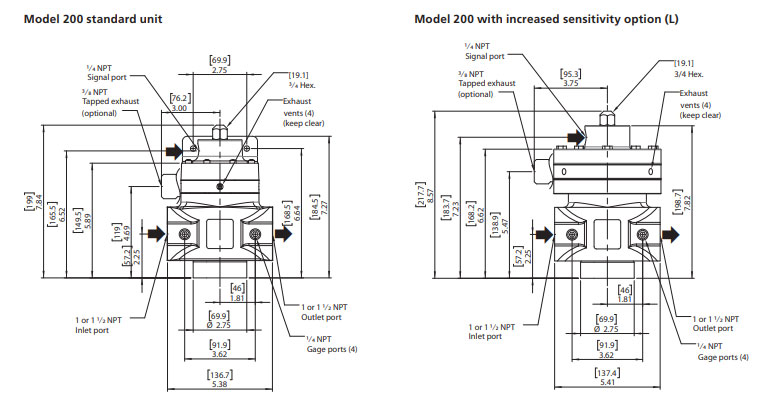

Dimensions

Model 200 Volume Booster Dimensions

Q & A

Model 200 Volume Booster System Q & A

Downloads

Download Rotork Fairchild Model 200 Pneumatic Volume Booster Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.