The Model 20 Volume Booster is a smaller pneumatic device capable of high flow and exhaust capacity. This device uses a force balance system to control the movement of the supply and exhaust valves.

The Model 20 Volume Booster is a smaller pneumatic device capable of high flow and exhaust capacity. This device uses a force balance system to control the movement of the supply and exhaust valves.

Operating Principles

The Model 20 volume booster is a pneumatic device capable of high flow and exhaust capacity. This device uses a force balance system to control the movement of the supply and exhaust valves.

At the setpoint, the force due to signal pressure that acts on the top of the upper diaphragm balances with the force due to output pressure acting on the bottom of the lower diaphragm.

Features

Model 20 Volume Booster Features

- A pneumatic input signal accurately controls output pressure

- A balanced supply valve minimizes the effects of supply pressure variation

- Aspirator tube compensates downstream pressure droop under flowing conditions

- Optional adjustable bypass needle valve option includes a bubble-tight exhaust valve, allows tuning for optimum dynamic response (1:1 ratio only), and cycle-free operation with valve positioners

- Optional fixed negative bias for pneumatic signal devices that cannot be adjusted to zero signal pressure

- A separate control chamber isolates the diaphragm from the main flow to eliminate hunting and buzzing

- Unit construction allows servicing without removal

- Mounting bracket available - easy installation in the field

- Suitable for use in all Canadian territories and provinces

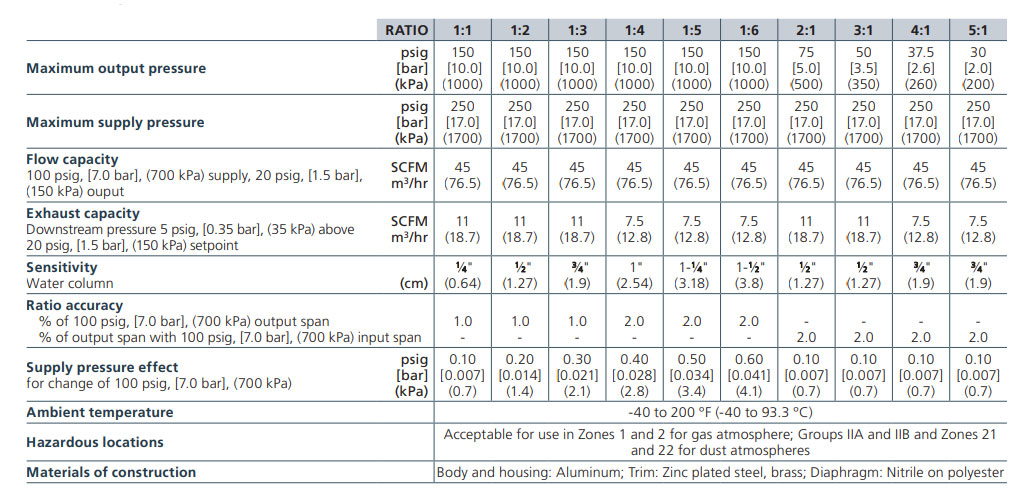

Specifications

Model 20 Volume Booster Specifications

Dimensions

Model 20 Volume Booster Dimensions

Q & A

Model 20 Volume Booster Q & A

The M20 is designed for straightforward installation and long-term reliability. It can be mounted easily using an optional bracket, and most servicing can be performed without removing the device from the line, minimizing downtime. For optimal performance, ensure the pneumatic signal supply is clean and dry to prevent diaphragm wear or clogging. Proper exhaust routing is also essential—depending on the model, you may have a straight or tapped exhaust, both of which should be vented safely. Although the M20’s balanced supply valve reduces the impact of pressure fluctuations, maintaining a stable supply will yield the best results. It’s also recommended to periodically inspect the diaphragms and fittings for leaks and verify the response time to confirm the unit is performing as expected. Installing the booster close to the actuator will further enhance response speed and stability.

Downloads

Download Rotork Fairchild Model 20 Pneumatic Precision Volume Booster Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.