Based on the Model 200 valve body, the Model 200XLR Volume Booster couples two identical units to obtain ultra-high flow capacity in both forward and exhaust modes. As a pilot-operated regulator design, the M200 is designed for high supply pressures and features ultra-high flow capacity.

Based on the Model 200 valve body, the Model 200XLR Volume Booster couples two identical units to obtain ultra-high flow capacity in both forward and exhaust modes. As a pilot-operated regulator design, the M200 is designed for high supply pressures and features ultra-high flow capacity.

Operating Principles

When signal pressure on the top of the signal Diaphragm creates a downward  force on the Diaphragm Assembly, the Supply Valve opens. Output pressure flows through the Outlet Port and the Aspirator Tube to the Control Chamber to create an upward force on the bottom of the Control Diaphragm. When the setpoint is reached, the downward force of the signal pressure that acts on the top of the Signal Diaphragm balances with the upward force of the output pressure that acts on the bottom of the Control Diaphragm.

force on the Diaphragm Assembly, the Supply Valve opens. Output pressure flows through the Outlet Port and the Aspirator Tube to the Control Chamber to create an upward force on the bottom of the Control Diaphragm. When the setpoint is reached, the downward force of the signal pressure that acts on the top of the Signal Diaphragm balances with the upward force of the output pressure that acts on the bottom of the Control Diaphragm.

When the output pressure increases above the signal pressure, the Diaphragm Assembly moves upward to close the Supply Valve and open the Exhaust Valve. Excess output pressure exhausts through the Exhaust Port until it reaches the setpoint.

Features

Model 200XLR Volume Booster Features

- The Model 200XLR Pneumatic Volume Booster produces a pneumatic signal in a 1:1 ratio. It is ideally suited for systems that require input isolation or increased forward and exhaust flow capacities.

- Control sensitivity to 1” water column variation.

- Large supply and Exhaust valves provide high forward and exhaust flows.

- An Aspirator Tube minimizes downstream pressure droop under flow conditions.

- A separate Control Chamber isolates the diaphragm from the main flow to eliminate hunting and buzzing.

- Optional Increased Sensitivity configuration with a larger Control Diaphragm for more precision control at low setpoints.

Specifications

Model 200XLR Volume Booster Specifications

- Flow Capacity (SCFM): In excess of 1500 (2550 m3/hr) @ 100 psig, [7.0 BAR],(700 kPa) supply and 20 psig, [1.5 BAR], (1500 kPa) set-point

- Exhaust Capacity (SCFM): 325 (552.5 m3/hr) where downstream pressure is 5 psig, [.35 BAR], (35 kPa) above 20 psig, [1.5 BAR], (150 kPa) setpoint

- Supply Pressure: 250 psig, [17.0 BAR], (1700 kPa) Maximum

- Supply Pressure Effect: Less than 0.5 psig, [.03 BAR], (3.4 kPa) for 100 psig, [7.0 BAR], (700 kPa) change in supply pressure

- Signal or Output Pressure: 150 psig, [10.0 BAR], (1000 kPa) Maximum

- Sensitivity: 1" (2.54 cm) Water Column

- Ambient Temperature: -40°F to +200° F, (-40°C to +93° C

- Materials of Construction:

- Body and Housing: Die Cast Aluminum

- Trim: Stainless Steel, Brass, Aluminum, and Zinc Plated Steel

- Diaphragms: Nitrile on Dacron

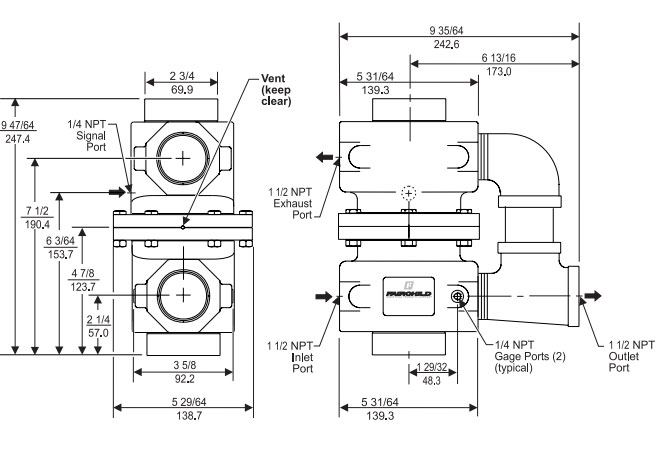

Dimensions

Model 200XLR Volume Booster Dimensions

Q & A

Model 200XLR Volume Booster Q & A

Proper installation and maintenance are essential to maximize the life and accuracy of the Fairchild 200XLR. The booster should be mounted according to the manufacturer’s manual and connected with clean, dry, and filtered air to prevent internal contamination or diaphragm damage. Its high exhaust capacity requires correctly sized venting to avoid back pressure during operation. Regular inspections for wear, debris, or diaphragm degradation will help maintain performance, and genuine Fairchild service kits are available throughout North America and Europe for easy maintenance. Ensuring that the unit operates within its specified temperature range and environmental limits will further enhance reliability in industrial facilities.

Downloads

Download Rotork Fairchild Model 200XLR Pneumatic Volume Booster Datasheet

Call us today at (855) 737-4714 to learn more, or fill out our online form and someone will get back to you.