Selecting the Perfect Regulator in Semiconductor Gas or Fluid Line Systems

How to Select the Perfect Pressure Regulator?

How to Select the Perfect Pressure Regulator

Therefore, it is crucial to?find reliable brands that can?meet the demands of the?industry when searching for?a pressure regulator. The next?step is to find a regulator?that fits the application -?with manufacturers typically?offering an extensive range of?sizes, this process may take?some time.

However, by following the aforementioned design standards and guidelines, you can ensure the integrity of your regulator and the overall system will remain intact.

Choosing the right regulator can have critical positive consequences.

In this whitepaper we will help simplify your selection process by covering what factors to consider for your application.

- A more efficient system

- Improved performance

- Reduced troubleshooting

- Reduced safety hazards

What factors should you?consider when selecting a?regulator?

Pressure regulators are?devices designed to maintain?and control gas or fluid?pressure. The ideal regulator?for your system depends?on your process and system?requirements. Here are the?key factors to consider when?selecting a regulator:

- Inlet and outlet pressure

- Flow requirements

- System temperature

- System media

- End connections

- Tied vs. non-tied diaphragm

Inlet and Outlet pressure?

Knowing the upstream?and downstream pressure?requirements of your line?or system sets the pressure?envelope, narrowing down the?field of regulators to choose?from. Ensure you know?the application's operating?pressure range and maximum?pressure for both the inlet?and outlet.

?

- Is your inlet pressure?stable, or does it fluctuate?

- Typically, source regulators?connected to a gas cylinder?will see a range of inlet?pressures. As the cylinder?depletes, inlet pressure to the?regulator reduces. In contrast,?regulators downstream?(I.e., part of a distribution?line being fed by a source?regulator) will hardly have?any fluctuation in inlet?pressure.

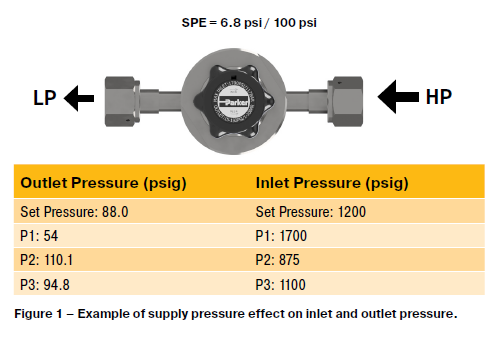

- Supply Pressure Effect?(SPE) - the regulator's outlet?pressure has an inverse?response to the inlet pressure?applied. SPE occurs due to the internal force balance?happening in the regulator.?It is measured as a rate of?change in outlet pressure per?every 100 psi change in inlet?pressure. The change between?inlet and outlet pressure is?inversed.

For example, if the SPE of?the regulator is rated at?6.8psi/100psi, the outlet?pressure will increase by a?rate of 6.8 psi per 100 psi?decrease of inlet pressure and?vice versa.?

Typically, the manufacturer?will publish SPE values.?Because systems with a?maximum pressure limit are?sensitive to SPE, it is common?to have a pressure relief valve?installed in-line to limit?maximum pressure.?

Another method to counteract?SPE is to add another?pressure regulator in-line?after the source regulator (or?use a two stage-regulator).??In this case, the source?regulator's outlet becomes?an intermediary to ballast?the pressure feeding the?downstream regulator,?reducing the effect of SPE?downstream.

?

figure 2?

Outlet Pressure

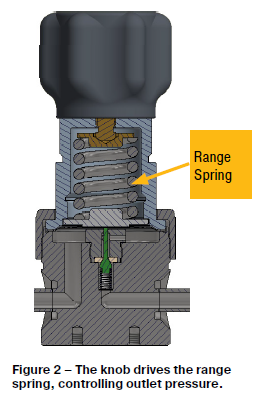

The outlet pressure range?of a regulator is determined?by the range spring. A lower?outlet pressure range would?have a "lighter" spring, while?a higher outlet pressure range?would have a "heavier" spring.

Sensitivity

The amount of spring force?produced by the range spring?directly correlates to flow?performance and adjustment?resolution of outlet pressure.?Lighter springs generally?produce less pressure drop?at flow and provide a finer?resolution of pressure?adjustment.

Therefore, sizing a regulator?for an application is critical?to achieving optimal?performance. Selecting a?regulator tailored to the?application by rounding up?the outlet pressure target?to the nearest outlet range?option is ideal for proper?sizing.

Systems can also have?varying operating pressures?when being fed by multiple?regulators. Especially if the?range of varying operating?pressures is wide, it is?inadvisable to go with a?"one-size fits all" selection?approach.

High-outlet pressure ranges?may not be suitable for low pressure?applications due?to the level of sensitivity. It?may not allow the precise?adjustability needed to reach?a target outlet pressure. In?addition, a high-pressure?regulator in a low-pressure?application will experience a?greater amount of pressure?drop at flow.

Flow Requirements

The flow rate of your system?requirements affects the size?of regulators you need.

?

typical flow curve?

Key Considerations:

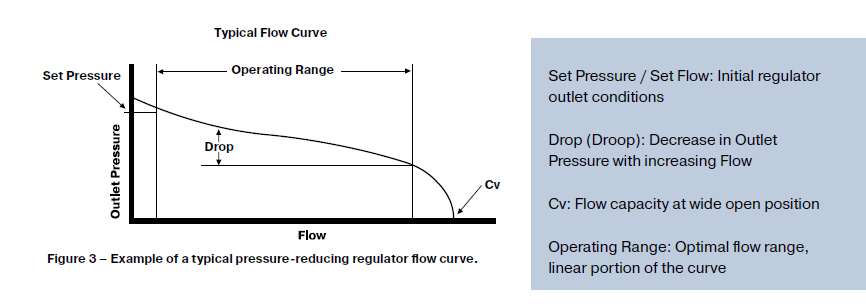

- It is best practice to verify?the inlet, outlet and flow?parameters with flow curves.

- Is the flow rate constant?or variable? Knowing the?flow schematic of the?system that a regulator is?feeding is important for?sizing. Regulators feeding?downstream can feed a single?line or branch to multiple?lines.

With branching lines, it is?good to know the operating?flow range and the peak?downstream flow to ensure?the regulator has the available?capacity to support all?conditions.

You can estimate downstream?flow demand by totaling?the flow capacity (Cv) of all?downstream valves that would?flow simultaneously in typical?and maximum conditions. - With those flow values?established, you should?reference a flow curve to ensure the flow demand is?within the operating range?of the regulator and that the?outlet pressure drop is within?an acceptable limit.

- Flow Options :?Manufacturers often provide?multiple flow options within?a product series to optimize?applications that demand?different flow levels.

- The published Cv of a?regulator should be taken?as a point of reference for?selection and can work for a?relative comparison.

It is not indicative of a?regulator's flow performance.?Unlike valves, regulators?do not operate in a fully?open state. In some cases,?manufacturers will indicate?the flow range of the product?series.

However, checking conditions?against a flow curve is always?recommended to verify if the?device's optimal flow range?supports the application.?Typically, the manufacturer?will provide flow curves at?common parameter settings.

You can often extrapolate?a flow curve between what?is published. In addition, manufacturer flow curves?are typically produced with?nitrogen at room temperature.?Be sure to take gas and?temperature correction into?account for your application.

System Temperature

Processes can reach extremes?in temperatures, especially?due to changes in pressure.?Your choice of regulators?must withstand the ranges of?temperatures that occur in?typical operating conditions.?System temperature and?media determine the most?suitable seal material option?for your application.

If the system operating?temperature exceeds the limit?of seal materials ratings, it can?cause leaks internally and/?or externally, which create?safety hazards and significant?downtimes.

System Media

The type of system media?(gas, liquid, or steam) along?with temperature will affect?the longevity of the regulator?you select. Surface treatments?such as electropolish and?passivation, in addition, to?surface finish, can cleanliness with stainless steel?regulators.

Another consideration is seal?materials. Metal regulators?are especially affected since?they are typically designed?with plastic or rubber seals.?Knowing media compatibility?will influence the decision on?the best seal material choice.

Media that is not compatible?can cause faster deterioration?and decrease the life?cycle, making the material?compatibility between your?regulator and your system?media a key consideration.?

End Connections?

End connection types are?usually synonymous with?the industry served and the?means to provide the level of?leak integrity needed.?For example, ultra-high?purity regulators used for?semiconductor processes?commonly have welded faceseal?or tube-end connections?due to more stringent leak?rates. On the other hand,?regulators for oil and gas?industries commonly use?National Pipe Thread Tapered?(NPT) connections.

?

Tied vs. Non-Tied?

Tied vs. Non-tied Diaphragm

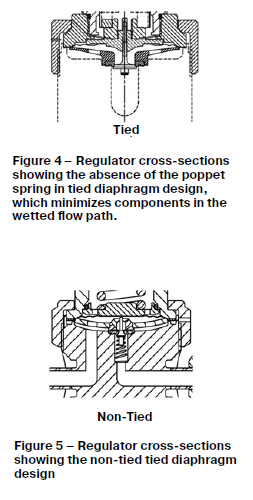

Tied diaphragm regulators?physically connect the poppet?to the diaphragm, resulting?in a mechanically assisted?positive shut-off acting as a?safety shut-off feature in the?event there is leakage across?the seal.

Tied diaphragms allow the?spring to be removed from?the wetted area, making?the operation far cleaner?and reducing particles that?could be generated during?operations.

Therefore, tied diaphragms?are preferred in ultra-high?purity (UHP) applications. In?applications with hazardous?and corrosive media, tied?diaphragms are considered an?added safety feature. However,?a tied diaphragm costs more?due to the increased number?of components.

Other factors to consider:

- Material of construction

- Cleanliness

- Leak rate

- Sensitivity of regulator

- Flow curve

Conclusion

No matter what your?application is, choosing the?proper regulator is vital. Your?regulator supplier can help with the selection process?by providing pressure and?flow requirements, sizing?information, temperature?ranges, and other essential?information.

A single regulator may?only address some of your?system requirements. If your?applications require regulators?with a wide range of flows,?a single high-flow regulator?type will need to be more?sensitive to handle your low-flow?applications.

Flow curves are a valuable?resource to ensure that your?regulator will match your?application for performance?optimization and process?optimization.

A regulator is not a shut-off?device. Instead, a valve should?be paired with the regulator?for a proper shut-off.

The better you understand?your application's?requirements, the more?equipped you will be to?make the right decision on a?pressure-reducing regulator.?Your supplier can provide?you with key specifications,?such as pressure and flow?requirements, temperature?ranges, and sizing for your?system needs.

?

Download Selecting the Perfect Regulator in Semiconductor Gas or Fluid Line Systems Whitepaper?

?

Call us today at (855) 737-4714, or fill out our online form and someone will get back to you.