No matter the direction, the Robotunits 24V Powered Roller Conveyor gently transports your goods according to your individual requirements. Robotunits' multifaceted system is ideally suited for zero-pressure accumulation conveying of goods, boxes, or other containers in industrial applications. Thanks to pre-installed control electronics, the Powered Roller Conveyor can be used immediately.

No matter the direction, the Robotunits 24V Powered Roller Conveyor gently transports your goods according to your individual requirements. Robotunits' multifaceted system is ideally suited for zero-pressure accumulation conveying of goods, boxes, or other containers in industrial applications. Thanks to pre-installed control electronics, the Powered Roller Conveyor can be used immediately.

Features

Powered Roller Conveyor System Features

- Variety of roller conveyor modules

- Plug and play, fully integrated control electronics

- Poly-V belt power transmission with integrated safety cover

- Modular layout allows for zero-pressure, energy-efficient conveying in all directions

- Immediate deployment, cost and time-efficient

- Safe and low maintenance

- Powered Roller Conveyor is certified for certain dimensions according to EN ISO 14644 for clean rooms.

Products

Powered Roller Conveyor System Products

Powered Roller Conveyor Straight

Powered Roller Conveyor Straight

Application: Zero-pressure accumulation of products in various sizes.

- 24V drive roller

- Rollers steel galvanized

- Power transmission through Poly-V belt

Aligning Powered Roller Conveyor

Aligning Powered Roller Conveyor

Application: Alignment of conveyed units of different sizes on one edge

- Brushless 24V DC motor

- Roller material: galvanized steel

- Conveyor rollers driven by Poly-V belts

- 10° offset rollers

- Free T-slots for side guide

Powered Roller Conveyor Merge

Powered Roller Conveyor Merge

Application: Zero-pressure accumulation conveying and merging into an existing conveyor line.

- For insertion at an angle of 45°

- Merging of multiple lanes into one main line

- Fully integrated control electronics

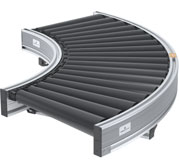

Powered Roller Conveyor Curved

Powered Roller Conveyor Curved

Application: Zero-pressure accumulation of products in various sizes.

- 24V drive roller

- Galvanized steel rollers with plastic sheathing

- Power transmission through a Poly-V belt

Transfer Unit 90°, 50

Transfer Unit 90°, 50

Application: 90-degree transfer of products in various sizes:

- Weight max. 50 kg: min. 300 x 400 to max. 800 x 800 mm

- Weight max. 20 kg: min. 300 x 400 to max. 400 x 1300 mm

The Transfer Unit 90° can be integrated into any Powered Roller Conveyor Straight zone.

Transfer Unit 90°, 100

Transfer Unit 90°, 100

Application: 90-degree transfer of products in various sizes from min. 400 x 600 to max. 1200 x 1200 mm.

- Max. weight of conveyed material: 100 kg

- Brushless 48V DC motor

- Integrated into any zone of a Powered Roller Conveyor Straight

- Compact, closed system

- Fully integrated control electronics

Turntable with Powered Roller Conveyor

Turntable with Powered Roller Conveyor

Application: Correctly positioned turning of products in various sizes.

- Correctly positioned turning of products from 0° to 270°

- Individual design of conveyors possible

- Compact overall height

Stand for Straight Conveyor

Stand for Straight Conveyor

Application: Stand for Powered Roller Conveyor Straight and Gravity Roller Conveyor Straight

Material:

- Satin anodized aluminum

- Galvanized GD-Zn

- Galvanized steel

- PA 6 or rubber

Stand for Curved Conveyor

Stand for Curved Conveyor

Application: Stand for Powered Roller Conveyor Curved 45° and Curved 90°

Material:

- Satin anodized aluminum

- Galvanized GD-Zn

- Galvanized steel

- PA 6 or rubber

Stand for Inclined Conveyor

Stand for Inclined Conveyor

Application: Stand for Powered Roller Conveyor Straight and Gravity Roller Conveyor Straight

Material:

- Satin anodized aluminum

- Galvanized GD-Zn

- Galvanized steel

- PA 6 or rubber

Q & A

Powered Roller Conveyor System Q & A

Downloads

Robotunits Conveyor Technology Catalog

Download Robotunits Stand for Conveyor Datasheet

Call us today at (855) 737-4716 to learn more, or fill out our online form and someone will get back to you.