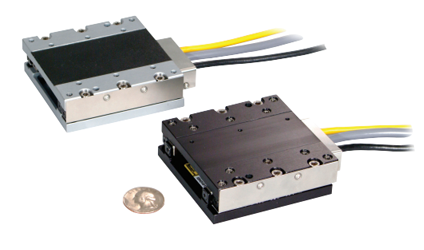

The Parker MX80L Miniature Linear Motor Stage is one of the smallest linear servo motor positioners in the industry, engineered for ultra-compact high-throughput automation systems. With a low profile of just 25 mm in height and 80 mm in width, it delivers rapid, precise motion for light-payload applications. Built for the demands of 24/7 production, the MX80L features a direct-drive linear motor design, cross-roller “zero cage-creep” guidance, integrated high-resolution encoder feedback, and options for clean-room and low-ESD environments.

The Parker MX80L Miniature Linear Motor Stage is one of the smallest linear servo motor positioners in the industry, engineered for ultra-compact high-throughput automation systems. With a low profile of just 25 mm in height and 80 mm in width, it delivers rapid, precise motion for light-payload applications. Built for the demands of 24/7 production, the MX80L features a direct-drive linear motor design, cross-roller “zero cage-creep” guidance, integrated high-resolution encoder feedback, and options for clean-room and low-ESD environments.

This linear servo motor stage is ideal for instrument builders, semiconductor metrology, biomedical automation and other high-performance motion applications in tight spaces.

Why Choose MX80L

In many modern automation systems, the challenge is: “How do you get high speed + high precision in a footprint that doesn’t compromise your instrument layout?” The MX80L answers that by putting a high-performance linear motor stage into a highly compact envelope.

Because the motion components (motor, encoder, bearings, sensors) are all integrated into the body, you gain a clean, reliable package with fewer external attachments—reducing complexity, increasing robustness and easing integration.

This stage is a strong contender for applications with light payload in high-throughput tasks needing to fit in restricted spaces (lab equipment, inspection machines, pick-&-place micro-components).

Features

MX80L Miniature Linear Motor Stage Features

- Ultra-compact footprint: 80 mm width × 25 mm height – supports integration in instruments where space is at a premium.

- Direct-drive linear servo motor: high thrust, high speed, and long life due to non-contact design.

- High acceleration & speed: velocities up to 2 m/s and acceleration up to ~5g, depending on configuration.

- Sub-micron precision feedback: selectable linear encoder resolutions from 0.01 μm to 5.0 μm.

- Cross roller bearings with “zero cage-creep”: enables smooth translation and high dynamic performance even under acceleration loads.

- Multi-axis platform ready: clean mechanical interface (dowel holes, master reference surface) simplifies integration into X-Y or multi-axis stacks.

- Clean-room & low ESD options: available for applications with stringent contamination or electrostatic requirements.

- No moving cables inside the stage: helps eliminate cable flex fatigue in high-duty or multi-axis systems.

Applications

MX80L Miniature Linear Motor Stage Applications

- Instrumentation and analytics (e.g., scanning, positioning in life-science systems)

- Semiconductor or microelectronics manufacturing (inspection, metrology, wafer handling)

- Biomedical automation (sample handling, microscopy stages)

- High-throughput pick-and-place or assembly of light payloads in constrained spaces

Specifications

MX80L Miniature Linear Motor Stage Specifications

| Parameter | Value* |

|---|---|

| Travel options | 25 mm, 50 mm, 100 mm, 150 mm (and in some cases up to 200 mm) |

| Max Payload (normal load) | 8 kg (≈18 lb) |

| Max Acceleration | Up to ~5g (varies by travel length and configuration) |

| Max Velocity | Up to ~2 m/s |

| Repeatability (bidirectional) | Precision grade: ±0.4 μm (with 0.02 μm encoder) |

| Straightness & Flatness | ~4 μm for shorter travels (precision grade) |

| Mounting interface features | Dowel holes on carriage top and base; master reference surface on side |

* Specifications based on Parker published data, subject to change/verification by Parker.

Q & A

MX80L Miniature Linear Motor Stage Q & A

Downloads

Download Parker MX80L Miniature Linear Motor Stage Datasheet

Download Parker MX80L Miniature Linear Motor Stage Product Manual

Call us today at (855) 737-4716 to learn more or fill out our online form and someone will get back to you.