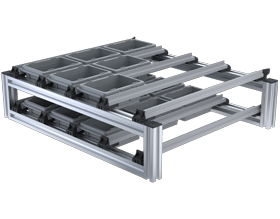

The MBS PickStar GL is particularly flexible and versatile. It can be used in combination with the aluminum round tube or the Robotunits aluminum extrusions and is ideal for short sliding sections and push-off stations in production lines.

The MBS PickStar GL is particularly flexible and versatile. It can be used in combination with the aluminum round tube or the Robotunits aluminum extrusions and is ideal for short sliding sections and push-off stations in production lines.

Benefits:

- Wide range of applications with quick-to-assemble components

- Long-term process reliability

- Greatest flexibility with minimum cost and effort

Features

MBS PickStar GL System Features

- Small number of multifunctional components, rolling or sliding as required

- Safe and strong frame design utilizing the Modular Automation System

- Track widths and inclination adjustable in just a few steps

- Default values

- Standard lengths up to 1200mm

- Surface resistance Rs < 100GΩ

- Load per rail: 1.5kg (L = 800mm, without guide)

- Load per rail: 2.5kg (L = 800mm, with guide)

- Rail material: PVC-U (anti-static)

- Adapter material: PA6, black (ESD conductive)

Applications

MBS PickStar GL System Applications

- Sliding sections

- Workstations

- Storage tracks

- Braking tracks

- Kanban racks and carts

- Transport carts

Products

MBS PickStar GL System Products

MBS PickStar GL - Round

MBS PickStar GL - Round

Advantages:

- Flexibly adjustable track width

- Simple assembly

- Freely selectable inclination

Application:

- Workstation with short tracks

MBS PickStar GL - Square

Advantages:

- Sturdy frame design

- Greater width

- Subsequent installation directly onto extrusions

Application:

- Integration into existing extrusion frames

Q & A

MBS PickStar GL System Q & A

The PickStar GL system is built for quick, intuitive installation. Its snap-in connectors and standardized extrusions eliminate the need for welding or specialized assembly tools. Maintenance is minimal since the system uses only a few multifunctional components, reducing spare parts inventory and complexity. The tight-fitting covers help protect against dirt and debris, while the low-noise sliding design reduces wear. Robotunits also provides downloadable installation guides, CAD files, and videos to support easy setup and maintenance over time.

Downloads

Download RobotUnits The Versatile MBS Pickstar Catalog

Call us today at (855) 737-4716 to learn more, or fill out our online form and someone will get back to you.