Benefits of Using a Ball Screw Stage in Automation

Screw-driven linear actuators—whether ball screw or lead screw type—offer an excellent balance of performance, cost, and integration flexibility for OEMs, machine builders, and integrators. At Valin Corporation, our portfolio of linear ball screw and lead screw actuators delivers proven performance for a wide range of applications—from high-thrust, long-travel modules to compact, light-duty embedded systems.

Screw-driven actuators convert rotary motor motion into linear translation via a screw and nut assembly. In ball screw designs, recirculating balls reduce friction and deliver higher efficiency and load capacity; lead screw designs offer simpler, cost-efficient solutions for moderate loads and lower duty cycles.

Use these actuators when you need:

- Controlled, repeatable motion with moderate to high force

- Defined travel length (including rod, rodless, slider, stage, and other form-factors)

- Flexibility of motor mounting, feedback integration, custom stroke, and mounting interfaces

- Cost-effective performance when ultra-high speeds or sub-micron, direct-drive control are not required

- Because Valin supports both ball screw and lead screw technologies, we help you select the right screw drive train for your performance, cost, and reliability trade-offs.

How to Choose the Right Actuator for Your Application

Knowing which actuator to select starts with understanding your loading, speed, travel and precision requirements. The LOSTPED acronym is very handy with this. Learn more about the Load, Orientation, Speed, Travel, Precision, Environment and Duty Cycle requirements in LOSTPED: What to Know About Selecting Mechanics.

Because Valin supports both ball screw and lead screw technologies, we help you select the right screw drive train for your performance, cost, and reliability trade-offs.

Features

Linear Ball Screw & Lead Screw Actuator Features

- Wide force & travel capabilities: From light duty to heavy thrust, stroke lengths of hundreds to thousands of millimeters, and loads into the hundreds of kilograms when configured.

- High reliability: Ball screw actuators offer reduced friction, longer life, and duty-cycle robustness.

- Cost-effective lead screw options: For many OEMs, a lead screw actuator offers the simplest solution where extreme speed or sub-micron, direct-drive repeatability isn’t required.

- Customization & modular flexibility: Support for different screw leads/pitches, nut preload options, motor types (stepper, servo), mounting surface variants, and feedback sensors.

- Integration readiness: Interfaces for multi-axis stacks, gantry systems, and OEM embedment.

- Application-tailored performance: Ideal for packaging machines, pick-and-place axes, inspection handling units, biomedical automation, and machine tool positioning.

Comparing Linear Actuators: Ball screws vs Lead screws

- Ball screws are more efficient than lead screws.

- Lead screws tend to cost less money than ball screws.

- Ball screws can back-drive whereas lead screws will lock in place.

Applications

Linear Ball Screw & Lead Screw Actuator Applications

- Precision assembly & pick-and-place equipment in electronics and consumer goods

- Machine tool axes, inspection/measurement systems, wafer handling in semiconductor manufacturing

- Laboratory automation, life-science instrumentation, and sample handling systems

- General automation where a robust, repeatable linear axis is required without the premium of a direct-drive linear motor

Products

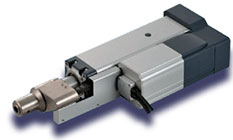

IAI's ELECYLINDER Series

Intelligent Actuators' ELECYLINDERS are designed to replace conventional pneumatic cylinders. ELECYLINDERS offer precise control, reduced cycle times, and enhanced reliability. With their direct control of acceleration and velocity, ELECYLINDERS ensure smoother, faster, and more accurate movements that pneumatic cylinders could never match. Whether in manufacturing, assembly, or any other form of automation, IAI’s ELECYLINDERS are the perfect fit for your applications.

Intelligent Actuators' ELECYLINDERS are designed to replace conventional pneumatic cylinders. ELECYLINDERS offer precise control, reduced cycle times, and enhanced reliability. With their direct control of acceleration and velocity, ELECYLINDERS ensure smoother, faster, and more accurate movements that pneumatic cylinders could never match. Whether in manufacturing, assembly, or any other form of automation, IAI’s ELECYLINDERS are the perfect fit for your applications.

Parker 400XR Series

The 400XR standard series linear positioners offer reliable performance and unmatched versatility. Convenient mounting features enable XY table combinations to be quickly and easily constructed. The XR family offers an unrivaled array of features and options that are easily matched to fit any application, from the very basic to the highly complex.

The 400XR standard series linear positioners offer reliable performance and unmatched versatility. Convenient mounting features enable XY table combinations to be quickly and easily constructed. The XR family offers an unrivaled array of features and options that are easily matched to fit any application, from the very basic to the highly complex.

Parker HMR Series

Parker's HMR actuator is a dual square rail guided actuator that boasts two different drive train options and five different frame sizes, along with a multitude of other configurable options, giving it superior loading capacity packaged in an extremely low-profile footprint, all with the intent of reducing overall design time and allowing for a clean and dramatically simplified integration into any machine layout.

Parker's HMR actuator is a dual square rail guided actuator that boasts two different drive train options and five different frame sizes, along with a multitude of other configurable options, giving it superior loading capacity packaged in an extremely low-profile footprint, all with the intent of reducing overall design time and allowing for a clean and dramatically simplified integration into any machine layout.

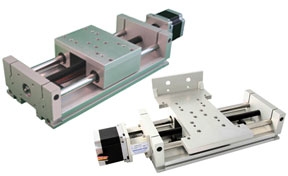

USAutomation Microstage 28

The Microstage 28 product line was designed with performance and price in mind. The basic housing of the Microstage28 is a precision machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with a precision profile linear bearing, A NEMA size 11 motor (28mm square) step motor and anti-backlash coupling are standard, and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

The Microstage 28 product line was designed with performance and price in mind. The basic housing of the Microstage28 is a precision machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with a precision profile linear bearing, A NEMA size 11 motor (28mm square) step motor and anti-backlash coupling are standard, and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

USAutomation Microstage 42

The Microstage 42 product line was designed with performance and price in mind. The basic housing of the Microstage 42 is a precision machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with a precision profile linear bearing, A NEMA size 17 motor (42mm square), step motor, and anti-backlash coupling are standard, and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

The Microstage 42 product line was designed with performance and price in mind. The basic housing of the Microstage 42 is a precision machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with a precision profile linear bearing, A NEMA size 17 motor (42mm square), step motor, and anti-backlash coupling are standard, and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

USAutomation Twintrac Positioning Stage

The Twintrac product line was designed with performance and price in mind. The base of the Twintrac is a precision-machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with precision round rails with two ceramic bearings on each rail. A NEMA size 23 motor (60mm square) step motor and anti-backlash coupling are standard and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

The Twintrac product line was designed with performance and price in mind. The base of the Twintrac is a precision-machined extrusion. The motion mechanism is comprised of a precision lead screw, with an anti-backlash nut, combined with precision round rails with two ceramic bearings on each rail. A NEMA size 23 motor (60mm square) step motor and anti-backlash coupling are standard and are included in the base price. End plate bearing housings, and motor mounts are universal throughout the product line.

Parker OSPE SB Ball Screw Actuator

The Parker OSPE SB ball screw driven rodless actuator is a cost-effective solution designed for light to medium industrial applications requiring precise positioning and high thrust forces at 100% duty cycle. The OSPE SB comes standard with a rigid internal slider bearing guide and is part of the Origa System Plus family, a family well known for high performance, high quality, and low cost of ownership.

The Parker OSPE SB ball screw driven rodless actuator is a cost-effective solution designed for light to medium industrial applications requiring precise positioning and high thrust forces at 100% duty cycle. The OSPE SB comes standard with a rigid internal slider bearing guide and is part of the Origa System Plus family, a family well known for high performance, high quality, and low cost of ownership.

Parker OSPE ST Trapezoidal Screw Actuator

The Parker OSPE ST trapezoidal (lead) screw driven rodless actuator is a cost-effective solution designed for light to medium industrial applications requiring high thrust forces and self-locking performance at 10% duty cycle. The OSPE ST comes standard with an internal slider bearing guide and is part of the Origa System Plus family, a family well known for high performance, high quality, and low cost of ownership.

The Parker OSPE ST trapezoidal (lead) screw driven rodless actuator is a cost-effective solution designed for light to medium industrial applications requiring high thrust forces and self-locking performance at 10% duty cycle. The OSPE ST comes standard with an internal slider bearing guide and is part of the Origa System Plus family, a family well known for high performance, high quality, and low cost of ownership.

IAI RCS3 Servo Press

The servo press provides superior stop stability while pressing, making it ideal for push-motion operation and other applications that require strong push-force, such as press fitting and riveting work. High-precision loading repeatability of 0.5% is possible using the feedback data from the dedicated load cell installed in the actuator.

The servo press provides superior stop stability while pressing, making it ideal for push-motion operation and other applications that require strong push-force, such as press fitting and riveting work. High-precision loading repeatability of 0.5% is possible using the feedback data from the dedicated load cell installed in the actuator.

Parker ETH Series High-Force Electric Cylinders

Electric cylinders are often in high-force, thrust-style applications, but with the advent of linear motor-driven cylinders, high-speed diverting applications are also available. Electric cylinders are commonly used in push-to-force, holding, reach and retract, and fluid power conversion applications. Parker offers a full range of cylinder products, each with a multitude of configurable options to suit almost any application. Pair these cylinders with Parker motor, drive, and control technologies to provide a complete solution.

Electric cylinders are often in high-force, thrust-style applications, but with the advent of linear motor-driven cylinders, high-speed diverting applications are also available. Electric cylinders are commonly used in push-to-force, holding, reach and retract, and fluid power conversion applications. Parker offers a full range of cylinder products, each with a multitude of configurable options to suit almost any application. Pair these cylinders with Parker motor, drive, and control technologies to provide a complete solution.

IAI EC-S18 EC-S18X Ultra Large Slider Type ELECYLINDER

The Ultra Large Slider Type ELECYLINDER? offers long vertical or horizontal strokes up to 2800 mm with high-speed performance up to 2000 mm/s, even on models with intermediate support. Its enhanced payload capacity—400 kg horizontally and 80 kg vertically—makes it suitable for heavy-duty lifting applications. A ball-screw support mechanism allows mounting in any orientation, while wireless teaching support enables easy setup even when the actuator is difficult to access.

The Ultra Large Slider Type ELECYLINDER? offers long vertical or horizontal strokes up to 2800 mm with high-speed performance up to 2000 mm/s, even on models with intermediate support. Its enhanced payload capacity—400 kg horizontally and 80 kg vertically—makes it suitable for heavy-duty lifting applications. A ball-screw support mechanism allows mounting in any orientation, while wireless teaching support enables easy setup even when the actuator is difficult to access.

IAI ELECYLINDER Stopper Cylinder EC-ST11

ELECYLINDER? Stopper Cylinders provide a compact, energy-efficient solution for conveyor stopper applications, requiring only a 24V power supply with no air source needed. Designed to handle radial impact loads, they support workpieces up to 30 kg, and collision speeds up to 30 m/min. With simple wireless operation, built-in control, 2-point positioning, and a rolling bushing structure, they offer reliable performance in a slim body width starting at 112 mm.

ELECYLINDER? Stopper Cylinders provide a compact, energy-efficient solution for conveyor stopper applications, requiring only a 24V power supply with no air source needed. Designed to handle radial impact loads, they support workpieces up to 30 kg, and collision speeds up to 30 m/min. With simple wireless operation, built-in control, 2-point positioning, and a rolling bushing structure, they offer reliable performance in a slim body width starting at 112 mm.

IAI's ELECYLINDER 5 Stopper Cylinder EC-ST15

IAI's ELECYLINDER 5 Stopper Cylinder EC-ST15 is ideal as a workpiece-stopper on a conveyor line without an air source for workpieces up to 50kg. The maximum collision speed of a workpiece is 40m/min.

IAI's ELECYLINDER 5 Stopper Cylinder EC-ST15 is ideal as a workpiece-stopper on a conveyor line without an air source for workpieces up to 50kg. The maximum collision speed of a workpiece is 40m/min.

Expert Advice

Integration & Support

- Download CAD models, 2D/3D drawings, and sizing tools.

- Use sizing calculators and motion-system calculators to evaluate screw lead, speed, life, and duty-cycle trade-offs.

- Learn from an example of sizing and selecting an electric actuator.

- Seek Application Engineering support for guidance on mounting, motor/feedback interface, and multi-axis layouts.

- Consider your customization options: lead/lead-nut configuration, nut preload, screw diameter & lead, motor type (stepper/servo), integrated feedback, mounting variations, and environmental sealing.

- Contact Valin’s team for a quote, lead-time, custom engineering, and product integration services.

Ready to select the right screw-driven linear actuator for your next machine build?

Download the screw-driven actuator catalogue, request a quote, and talk to one of our Valin motion control engineers about matching the right drive-train to your application.

Maintenance Tips to Extend the Lifespan of Your Actuator

- Make sure it is sized properly.

- Minimize the moment loading applied to it.

- Lubricate it periodically if it doesn’t include self-lubricating mechanical components; consult the user or maintenance manual for the specific actuator.

- Keep it free from contamination.

- If the shorts are repeated very short strokes that are less than the circumference of the ball bearings, then occasionally move it with longer travel to properly lubricate the ball bearings.

Q & A

Linear Ball Screw & Lead Screw Actuators Q & A

A ball screw actuator uses recirculating ball bearings in the nut-screw interface with U-shaped grooves to convert rotational motion to linear, resulting in lower friction, higher efficiency, better life, and typically less backlash. Lead screw actuators may use sliding or rolling contact with a threaded nut on a screw with V-shaped grooves, which is simpler and more cost-effective but may have higher friction or wear.

Under enough load, such as vertical applications, ball screw actuators will back-drive if there is no holding torque or brake on it. Lead screws will not which is why, especially for vertical loads, lead screw actuators are more attractive.

Choose a ball screw when your application demands long life, high duty-cycle, higher thrust, low friction, and high repeatability. Choose a lead screw when cost, simpler mechanism, lower speed/force, or smaller size are more critical. The best choice depends on your application metrics (force, speed, travel, cycle life, cost) rather than a one-size-fits-all.

Yes. Screw-driven actuators (ball screw or lead screw) can be integrated into X-Y, X-Y-Z, or gantry configurations, with proper guidance, motors, control, and cabling. While linear motors often dominate ultra-high-speed or sub-micron axes, screw-driven actuators provide excellent value for many machine motion axes.

Backlash is a common concern—ball screw pre-load or anti-backlash nuts mitigate it. Maintenance depends on environment and duty; ball screws typically require less frequent service than sliding-nut lead screws. The correct sizing and interface selection is key.

Valin brings deep motion-control system expertise (the three-tier framework: basic → precision → beyond), a broad actuator product portfolio (ball screw, lead screw, linear motors), OEM application know-how (especially in the Western US region), integration support, custom sizing & engineering assistance. We help you avoid selecting “because it looks cheap” and instead select “because it meets the real motion system metrics”.

Each ball screw and lead screw positioning system consists of essential components that directly impact performance and reliability:

- Ball screw or lead screw: converts rotary motion into linear motion.

- Guide rails: ensure smooth and precise linear travel.

- Carriage, Stage, or Slide Table: supports the load and attaches to the end-effector or tooling.

- Motor and Drive system: determines the motion profile, speed, and control interface.

Linear encoder: an option feedback device that enhances system accuracy in closed-loop systems.

If you have any questions or are just looking for some help, we're happy to discuss your application with you. Reach out to us at (855) 737-4716 or fill out our online form.