Dehydrate Wet Transformers Without Taking Them Out of Service!

Dehydrate Wet Transformers Without Taking Them Out of Service!

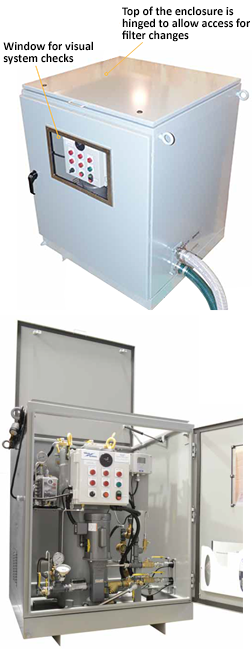

The Parker Velcon TDS? transformer dry-out system incorporates all the necessary features to allow a transformer to remain in-service while moisture from its insulation is effectively removed. The system is safe with several alarm features that shut the system off, isolating it from the transformer, in the event of any abnormal signal. The TDS5-MK1 unit provides a non-intrusive, cost effective and convenient method of maintaining transformers in a dry condition. In addition, once the transformer is dried, the system can be retrofitted with Activated Alumina cartridges to reduce acidity in the transformer oil. This flexibility allows increased oil processing application compared to heat and vacuum systems.

System Overview

The TDS? oil processing system is designed to allow a transformer under load to dry itself out. A quantity of four part number SD-1107 Superdri? cartridges can be installed in the filter vessel, through which oil is processed at a rate of 5 gpm. The filtering system removes dissolved water from oil to less than 10 ppm, and includes 1 micron nominal particle removal

capabilities. The process does not affect dissolved gas in oil, and does not remove oil oxidation inhibitors. The system is complete with all components necessary to monitor the mechanical and electrical operating conditions of the unit. The system includes components to purge air during start up and after filter changes.

Features

TDS?-5 Series On-Line Transformer Dryout System Features:

- Transformer remains in-service during process

- Reduce transformer dry-out costs

- Improve oil dielectric values

- Improve transformer power factor

- Operates continuously unattended

- Extend oil service life

- Extend transformer service life

- Built-in moisture sensor

Specifications

TDS?-5 Series On-Line Transformer Dryout System Specifications:

Dimension:

- Depth: 36”

- Width: 38”

- Height: 49” (85” with lid open)

- Shipping Weight: 1,125 lbs

Applications

TDS?-5 Series On-Line Transformer Dryout System Applications:

- Dry wet transformers and insulation

- Dry transformers not braced for vacuum

- Dry transformers that cannot be taken out of service

Q&A

TDS?-5 Series On-Line Transformer Dryout System Q & A:

The system operates by circulating transformer oil through SuperDri? cartridges, which adsorb dissolved water. Oil is drawn from the transformer's bottom fill connection and returned via a top connection valve. The process is continuous and unattended, allowing for 24-hour operation without interrupting transformer service.

No, the TDS?-5 Series is designed to remove dissolved water and particulates without affecting dissolved gases or removing oil oxidation inhibitors. This approach helps maintain the original characteristics of the transformer oil.

Yes, after the transformer has been dried, the TDS?-5 Series can be retrofitted with Activated Alumina cartridges to further process the oil by removing acidity. This flexibility allows for enhanced oil purification compared to heat and vacuum systems.

Downloads

Download Parker Velcon TDS 5 Series On Line Transformer Dryout System Datasheet

Talk to one of our filtration experts today at (855) 737-4717, or fill out our online form to learn more.